Cutting 1mm slots / rings for rosettes

Cutting 1mm slots / rings for rosettes

Hi Folks.

A quickie:

I've always found it tricky - in fact, downright frustrating and aggravating - trying to inlay the typical 1mm rings that are commonly used as part of the rosette in a steel-stringed guitar.

Y'know; you carefully cut a 1.5mm deep ring around the sound-hole to inlay mother-of-pearl into the soundboard, using very sharp tools so that there will be no frayed, wobbly or misshapen edges, then either successfully rout out the "meat" with a Dremel in a StewMac rosette cutter, a small chisel or even a tiny router plane. This never seems to be a problem

You then decide that you'd like to inlay an inner and an outer thin black/white/black ring made up of 0.3mm veneers (i.e. a total thickness of 0.9mm). It's really hard to make tiny concentric cuts 1mm apart for each ring (then try to neatly chisel or router-plane the scrap out), so you decide to use a down-cut bit.

And so you search your collection of imperial down-cut bits from Stewmac thinking that the 3/64" should do the trick, and you chuck it into the Dremel, set the depth to 1.5mm, shellac the soundboard (say, a stringy sort of spruce) where you're about to cut - and go for it.

The cut is somewhat fuzzy, and seems to be wider in some places than others. Maybe it's the bearings on the Dremel (there always seems to be some spot in the speed range where it seems to develop a "speed wobble").

Maybe it's "just the wood", or perhaps the bit's not sharp. Maybe the central hole that you've drilled into the soundboard to take the StewMac rosette cutter is just a bit loose, so that you're not cutting an exact circle.

You change to your other Dremel(!) that you know(!) has better, newer bearings. Of course you can't quite line up exactly the second "repairing!" cut with the first, so you inevitably make the slot a smidgen wider.

Eventually there's a less than satisfactory, bit wobbly ring, and if you look closely you see glue where veneer should be, and you're disgruntled because you wanted a crisp, perfect fit of the veneer ring into the groove. You try spraying everything with water to subtly swell the soundboard and / or veneers, so that the gaps will shrink. Ends up a mess.

So, whaddaya do to get a perfect inlay every time?

Frank.

A quickie:

I've always found it tricky - in fact, downright frustrating and aggravating - trying to inlay the typical 1mm rings that are commonly used as part of the rosette in a steel-stringed guitar.

Y'know; you carefully cut a 1.5mm deep ring around the sound-hole to inlay mother-of-pearl into the soundboard, using very sharp tools so that there will be no frayed, wobbly or misshapen edges, then either successfully rout out the "meat" with a Dremel in a StewMac rosette cutter, a small chisel or even a tiny router plane. This never seems to be a problem

You then decide that you'd like to inlay an inner and an outer thin black/white/black ring made up of 0.3mm veneers (i.e. a total thickness of 0.9mm). It's really hard to make tiny concentric cuts 1mm apart for each ring (then try to neatly chisel or router-plane the scrap out), so you decide to use a down-cut bit.

And so you search your collection of imperial down-cut bits from Stewmac thinking that the 3/64" should do the trick, and you chuck it into the Dremel, set the depth to 1.5mm, shellac the soundboard (say, a stringy sort of spruce) where you're about to cut - and go for it.

The cut is somewhat fuzzy, and seems to be wider in some places than others. Maybe it's the bearings on the Dremel (there always seems to be some spot in the speed range where it seems to develop a "speed wobble").

Maybe it's "just the wood", or perhaps the bit's not sharp. Maybe the central hole that you've drilled into the soundboard to take the StewMac rosette cutter is just a bit loose, so that you're not cutting an exact circle.

You change to your other Dremel(!) that you know(!) has better, newer bearings. Of course you can't quite line up exactly the second "repairing!" cut with the first, so you inevitably make the slot a smidgen wider.

Eventually there's a less than satisfactory, bit wobbly ring, and if you look closely you see glue where veneer should be, and you're disgruntled because you wanted a crisp, perfect fit of the veneer ring into the groove. You try spraying everything with water to subtly swell the soundboard and / or veneers, so that the gaps will shrink. Ends up a mess.

So, whaddaya do to get a perfect inlay every time?

Frank.

Re: Cutting 1mm slots / rings for rosettes

You can get carbide bits out of China in all kinds of sizes. I have them from 0.5mm through to 2.0mm in the 3mm shaft. They are so inexpensive that it won't bring you to tears when you break one. Ususally sold in a pack of 10.

So my recommendation is that you get one that is smaller than you need and sneek up on the size you want.

So my recommendation is that you get one that is smaller than you need and sneek up on the size you want.

- Mark McLean

- Blackwood

- Posts: 1174

- Joined: Thu Apr 10, 2008 2:03 pm

- Location: Sydney

Re: Cutting 1mm slots / rings for rosettes

Gerard Gilet showed me a trick that really helps. It is mentioned in "The Books". Cut the channel a little bit thinner than the width of the purfling material that you are using. For the 0.9mm BWB that you mention in your example you might cut a channel of 0.75 or 0.8. Then scrape off the bottom inside edge of the BWB strip using a cabinet scraper or razor blade. I scrape off the inside black layer, but only on the bottom half or third of the strip. Now your strip has a slight wedge profile. It is easy to slip the narrow side into the channel and then tap it down so that the fatter outer edge actually compresses the surrounding soundboard timber just slightly. Nice and tight! Gerard also recommends cutting the channel very slowly, full depth, in one pass. Doing it in multiple passes makes it more likely to introduce some variation. I think we have all had the experience of trying one extra pass "to clean it up", only to find that last run actually makes it worse. And like Allen said - new bits. I think you have to consider those things as pretty much disposable single use tools.

Re: Cutting 1mm slots / rings for rosettes

I also use a jewellers metal roller press to size all my purfling strips. Expensive item for sure, but does make all the difference when you are going for the perfect fit for things like rosettes.

No need to scrape the purflings. Just run them through the press and make them a nice slip fit. A tiny bit of glue then swells them up to fill any imperfections you might have.

No need to scrape the purflings. Just run them through the press and make them a nice slip fit. A tiny bit of glue then swells them up to fill any imperfections you might have.

Re: Cutting 1mm slots / rings for rosettes

As Allen recommends above, the bits from China work great for detail work (but i would not recommend the larger router bits from there... i found some to be dangerous and now wont use them).

Search ebay for CNC carbide router bits - from memory i got a pack of 10 for under $10 including shipping!

Search ebay for CNC carbide router bits - from memory i got a pack of 10 for under $10 including shipping!

- Trevor Gore

- Blackwood

- Posts: 1643

- Joined: Mon Jun 20, 2011 8:11 pm

Re: Cutting 1mm slots / rings for rosettes

For precision results, it helps a lot to have precision tooling.

Over the years, as I been asked to do more interesting rosettes, I've had to develop the tooling accordingly.

I use De Walt routers with precision aftermarket collets and bits. I use a much larger diameter pivot than is typical. Mine is 10mm diameter. I need to be able to drop into discontinuous cuts and finish them with precision. An anti-backlash radius adjuster is pretty much essential. Mine has a screw pitch of 1mm, so a 0.1mm adjustment either way can be made reliably and repeatably. I even had a digital readout (0.01mm) on this at one time, but found just using the screw was accurate enough. I have both 1/4" and 1/8" collets so that I don't need to use adapters.

The process is important, too. You usually don't get a second chance going around when cutting very fine slots.

Here's a couple of shots of the hardware:

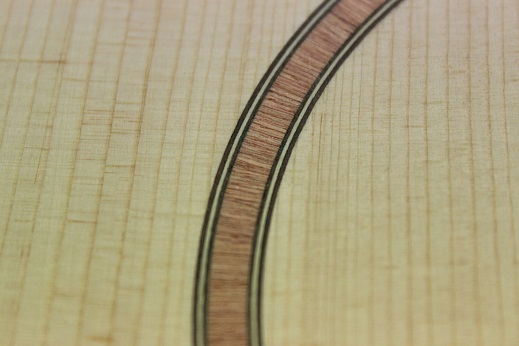

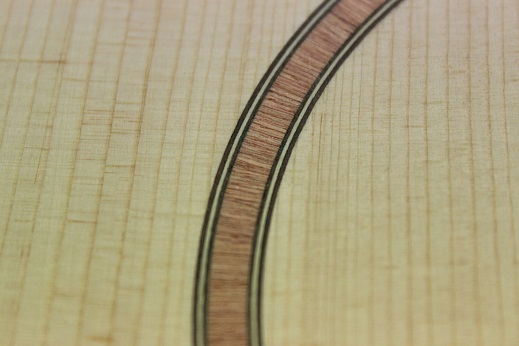

Here's an in-process shot...

...and a couple of outcomes.

Over the years, as I been asked to do more interesting rosettes, I've had to develop the tooling accordingly.

I use De Walt routers with precision aftermarket collets and bits. I use a much larger diameter pivot than is typical. Mine is 10mm diameter. I need to be able to drop into discontinuous cuts and finish them with precision. An anti-backlash radius adjuster is pretty much essential. Mine has a screw pitch of 1mm, so a 0.1mm adjustment either way can be made reliably and repeatably. I even had a digital readout (0.01mm) on this at one time, but found just using the screw was accurate enough. I have both 1/4" and 1/8" collets so that I don't need to use adapters.

The process is important, too. You usually don't get a second chance going around when cutting very fine slots.

Here's a couple of shots of the hardware:

Here's an in-process shot...

...and a couple of outcomes.

Fine classical and steel string guitars

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Re: Cutting 1mm slots / rings for rosettes

I find a scraper blade makes a huge difference for getting a clean edge on the inner and outer circumference.

Definetly hog the bulk out with a power tool, Dremel, router or what have you.

I like trev’s Setup, quality router with good bearings.

Scraper used on the edges of this one, does not matter how big or how small the channel.

I also find, I cut a channel first then worry about fitting, a razor blade scraper can do wonders

Steve

Definetly hog the bulk out with a power tool, Dremel, router or what have you.

I like trev’s Setup, quality router with good bearings.

Scraper used on the edges of this one, does not matter how big or how small the channel.

I also find, I cut a channel first then worry about fitting, a razor blade scraper can do wonders

Steve

Re: Cutting 1mm slots / rings for rosettes

I've tried loads of things over the years. The best results happened when I started adding mass to the whole setup. I bought several of these when I was in Germany:

https://www.ebay.de/itm/Fraszirkel-fur- ... Swo4pYI2gc

There may be something similar in Oz.

I have them set up permanently. I don't adjust them at all. One for each cut I want to make, so no adjusting. Each one has a laminate trimmer bolted into place. You can buy trimmers for next to nothing these days. I have one set just for cutting soundholes.

The extra mass really seems to make the difference.

Also, these Dremel bits are great for rosettes - you get about half a dozen channels cut out before you have to chuck them, but I've never had a chip yet from one yet. At 7.8mm across, they are wide enough for many designs. Give the top a quick wipe/stiffen with shellac and you're ready to go.

https://www.ebay.de/itm/Fraszirkel-fur- ... Swo4pYI2gc

There may be something similar in Oz.

I have them set up permanently. I don't adjust them at all. One for each cut I want to make, so no adjusting. Each one has a laminate trimmer bolted into place. You can buy trimmers for next to nothing these days. I have one set just for cutting soundholes.

The extra mass really seems to make the difference.

Also, these Dremel bits are great for rosettes - you get about half a dozen channels cut out before you have to chuck them, but I've never had a chip yet from one yet. At 7.8mm across, they are wide enough for many designs. Give the top a quick wipe/stiffen with shellac and you're ready to go.

Re: Cutting 1mm slots / rings for rosettes

This is really excellent; so many good ideas, and from a group of people who have proven in-depth knowledge and are known to be creators of really amazing work.

Thanks for all your suggestions, from sublime professional tools and jigs shown, to the ridiculously cheap but no doubt very effective suggestions of Chinese router bits..

I spent a few hours searching eBay for bits and pieces (actually, more bits), and ordering some that will fit into my Dremels. I'm not really sure what I've bought, to be honest; Two, three or four flutes; "flat nose end mill router bit"; TiN-coated carbide end milling cutter"; "mills carbide engraving tips"; "carbide Dremel drill bit router"; "4 flute end mill cutter drill bit"! So I bought a few of each. And I could see nowhere words like "up-cut" or "down-cut" about which place like StewMac or LMII wax lyrical. Maybe after all my searching, all I've bought are drill bits, and not router bits!

As one gets down in thickness to 0.3mm - or even 1.0mm, for that matter - the cutting parts seem impossibly thin compared to their length. I keep wanting to say "just make the flippin' thing shorter, so that it won't snap as soon as you apply any sideways force to the tip"! I can see why and how some of these really thin objects can be used as drills; but as router bits? Dunno. I guess I'll see.

As always, I'm prepared to try and unscrew the unscrewtable in my quest for knowledge and mastery. So I'll wait until that impossibly slow juggernaut that is the Chinese (free) postal system deposits these treasures onto our shores. Roll on June!

Frank.

Thanks for all your suggestions, from sublime professional tools and jigs shown, to the ridiculously cheap but no doubt very effective suggestions of Chinese router bits..

I spent a few hours searching eBay for bits and pieces (actually, more bits), and ordering some that will fit into my Dremels. I'm not really sure what I've bought, to be honest; Two, three or four flutes; "flat nose end mill router bit"; TiN-coated carbide end milling cutter"; "mills carbide engraving tips"; "carbide Dremel drill bit router"; "4 flute end mill cutter drill bit"! So I bought a few of each. And I could see nowhere words like "up-cut" or "down-cut" about which place like StewMac or LMII wax lyrical. Maybe after all my searching, all I've bought are drill bits, and not router bits!

As one gets down in thickness to 0.3mm - or even 1.0mm, for that matter - the cutting parts seem impossibly thin compared to their length. I keep wanting to say "just make the flippin' thing shorter, so that it won't snap as soon as you apply any sideways force to the tip"! I can see why and how some of these really thin objects can be used as drills; but as router bits? Dunno. I guess I'll see.

As always, I'm prepared to try and unscrew the unscrewtable in my quest for knowledge and mastery. So I'll wait until that impossibly slow juggernaut that is the Chinese (free) postal system deposits these treasures onto our shores. Roll on June!

Frank.

- lamanoditrento

- Blackwood

- Posts: 617

- Joined: Thu May 05, 2016 9:50 am

Re: Cutting 1mm slots / rings for rosettes

At the Brisbane AGMS we now wash the rosette area with CA rather than shellac (before cutting and any end grain is exposed) after seeing it on the Michael Greenfield vid. We haven't had a student build with fuzziness from the SM dremel circle cutter since.

Trent

Re: Cutting 1mm slots / rings for rosettes

Trevor you mention third party high quality collets for the dewalt routers you use. A quick search doesn’t give an obvious supplier. Without getting too commercial where should we be looking - the cnc tooling people perhaps...?

I was surprised to see the specs of such devices, the best are seriously better than the ordinary ones.

I was surprised to see the specs of such devices, the best are seriously better than the ordinary ones.

------------------

Dave

Dave

-

blackalex1952

- Blackwood

- Posts: 775

- Joined: Tue Aug 27, 2013 6:36 pm

- Location: North East Victoria

Re: Cutting 1mm slots / rings for rosettes

Moonshala wrote

I use Kyocera diamond downcut bits. They are available on ebay occasionally and from https://www.mytoolstore.com.au/products ... BURRS.html

Other sizes available as well. I use the larger diameter for hogging out, the for fine points I use the thin ones and sometimes even a sharp scalpel for refining. High speed is the key for inlay bits.

Also available is this:http://www.bluescreekguitars.com/shop/i ... ucts_id=18

Runs on compressed air at much higher speed than a Dremel. There are others available as well in the marketplace. They run at much higher speed than a Dremel.

Robbie O'Brien vids are great:https://www.youtube.com/watch?v=ifWqNtgKa1E

-Ross

The idea with the thin dremel bits is to use highest speed available on the Dremel and to let the tool do the work. Any sharp tool in luthierie must do the work, not the brute force applied. Applying force to a blunt tool only results in disaster. When using chisels and carving tools, for example, the last cut should be done with the sharpest blade. Touching blades up regularly means less work resharpening if the blade is left to go really blunt.As one gets down in thickness to 0.3mm - or even 1.0mm, for that matter - the cutting parts seem impossibly thin compared to their length. I keep wanting to say "just make the flippin' thing shorter, so that it won't snap as soon as you apply any sideways force to the tip"! I can see why and how some of these really thin objects can be used as drills; but as router bits? Dunno. I guess I'll see.

I use Kyocera diamond downcut bits. They are available on ebay occasionally and from https://www.mytoolstore.com.au/products ... BURRS.html

Other sizes available as well. I use the larger diameter for hogging out, the for fine points I use the thin ones and sometimes even a sharp scalpel for refining. High speed is the key for inlay bits.

Also available is this:http://www.bluescreekguitars.com/shop/i ... ucts_id=18

Runs on compressed air at much higher speed than a Dremel. There are others available as well in the marketplace. They run at much higher speed than a Dremel.

Robbie O'Brien vids are great:https://www.youtube.com/watch?v=ifWqNtgKa1E

-Ross

Last edited by blackalex1952 on Tue Apr 10, 2018 11:45 am, edited 1 time in total.

"Everything I say on the topic is based solely upon inexperience and assumption!"

-

blackalex1952

- Blackwood

- Posts: 775

- Joined: Tue Aug 27, 2013 6:36 pm

- Location: North East Victoria

Re: Cutting 1mm slots / rings for rosettes

As regards to the use of superglue on raw spruce, I have found occasionally that the superglue stains the wood a greenish tint. Does anybody else experience this and what would the reason be for it only happening on some spruce samples and not others?

Ross

Ross

"Everything I say on the topic is based solely upon inexperience and assumption!"

- Trevor Gore

- Blackwood

- Posts: 1643

- Joined: Mon Jun 20, 2011 8:11 pm

Re: Cutting 1mm slots / rings for rosettes

I was asked this question in another recent thread here:Dave M wrote: ↑Tue Apr 10, 2018 9:05 amTrevor you mention third party high quality collets for the dewalt routers you use. A quick search doesn’t give an obvious supplier. Without getting too commercial where should we be looking - the cnc tooling people perhaps...?

I was surprised to see the specs of such devices, the best are seriously better than the ordinary ones.

You need the full kit: collet or collets (if going 1/4" and 1/8"), nut and wrench. You may want to order some cutters at the same time.Trevor Gore wrote: ↑Sun Apr 08, 2018 1:01 pmPrecise Bitsblackalex1952 wrote: ↑Sun Apr 08, 2018 10:32 amTrevor Gore...Where do you get the precision aftermarket collets and bits? Ross

As it happens, I also have a Makita router that just lucked out with a really accurate collet. With the Precise collets you get the tolerance you order, never better by chance. I think they get made all the same and are then selected for accuracy.

Most half decent trimmers seem to have pretty accurate shafts and bearings, but are nearly always seriously let down by their collets.

Fine classical and steel string guitars

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Trevor Gore, Luthier. Australian hand made acoustic guitars, classical guitars; custom guitar design and build; guitar design instruction.

Re: Cutting 1mm slots / rings for rosettes

Canary yellow is the popular one. Some superglues do this, some don't. I'm not sure what the magic ingredient is. If like me, you get your superglue from the discount shop, you'll avoid using CA for this job. Shellac is a lot safer. It's easy to use and dirt cheap. You don't have to worry about the "cut" or the colour or the wax content. You can just slap some on, as it'll be coming off later.blackalex1952 wrote: ↑Tue Apr 10, 2018 11:41 amAs regards to the use of superglue on raw spruce, I have found occasionally that the superglue stains the wood a greenish tint. Does anybody else experience this and what would the reason be for it only happening on some spruce samples and not others?

Ross

Superglue - Sometimes it takes a day for the yellow to show. I found out the hard way - I sealed the binding on ten guitars in one go. Came in the next day to find them all stained canary yellow.

You can't sand it out.

I did a lot of sunbursts that year.

If you find a brand that doesn't do it, great. But that doesn't mean the makeup of the glue won't change at some time. You'll only find out when it's too late.

Nigel

- lamanoditrento

- Blackwood

- Posts: 617

- Joined: Thu May 05, 2016 9:50 am

Re: Cutting 1mm slots / rings for rosettes

Yes there is some staining with CA on spruce, however if it is on the surface of the plate you are about to inlay, I find sanding it off no problem at all (although a bit more than if you just shellac). However the difference in the crispness and sharp edge to me is so worth it.blackalex1952 wrote: ↑Tue Apr 10, 2018 11:41 amAs regards to the use of superglue on raw spruce, I have found occasionally that the superglue stains the wood a greenish tint. Does anybody else experience this and what would the reason be for it only happening on some spruce samples and not others?

Ross

CA ANYWHERE near end grain though and it will wick in impossibly deep and you will sand through the SB before getting rid of that yellow/green.

Trent

Who is online

Users browsing this forum: No registered users and 83 guests