Variations on a Macca.

- Bob Connor

- Admin

- Posts: 3115

- Joined: Mon Jul 09, 2007 9:43 pm

- Location: Geelong, Australia

- Contact:

-

Joe Sustaire

- Myrtle

- Posts: 92

- Joined: Sun Nov 23, 2008 1:23 am

- Location: Talihina Oklahoma

- Contact:

Wow, what can I say Nick, that binding/perf line-up on a dovetail neck to body joint is astonishing!

And I very much appreciate your pics showing your jigging for the dovetail joint. I'm getting ready to set up jigging for dovetail neck joint and am absorbing what info I can find.

Thanks,

Joe

And I very much appreciate your pics showing your jigging for the dovetail joint. I'm getting ready to set up jigging for dovetail neck joint and am absorbing what info I can find.

Thanks,

Joe

The only safe thing to do, is to take a chance! Mike Nichols

-

Paul B

- Nick

- Blackwood

- Posts: 3628

- Joined: Thu Feb 26, 2009 11:20 am

- Location: Christchurch, New Zealand

- Contact:

Thanks Paul but as I pointed out to Joe on the LuthierCom forum, I don't want to raise the bar too high because I'm only a short arse and if I do then I might not be able to reach me beer.Paul B wrote:I've been watching this thread with my jaw hanging open. You are certainly raising the bar. Thanks for sharing.

"Jesus Loves You."

Nice to hear in church but not in a Mexican prison.

Nice to hear in church but not in a Mexican prison.

- Nick

- Blackwood

- Posts: 3628

- Joined: Thu Feb 26, 2009 11:20 am

- Location: Christchurch, New Zealand

- Contact:

Things still continue to move slowly on this build (damn outside 'distractions'  ) But I thought I'd just post some pics to show where Im at.

) But I thought I'd just post some pics to show where Im at.

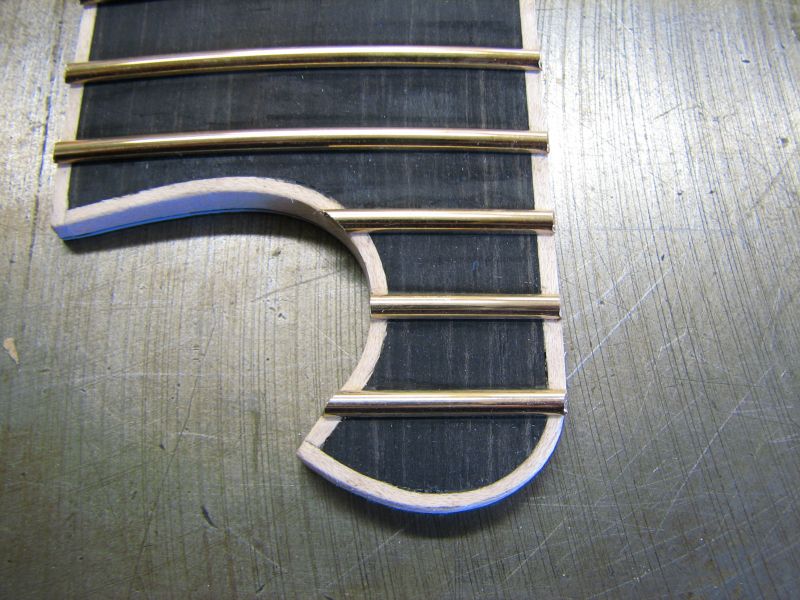

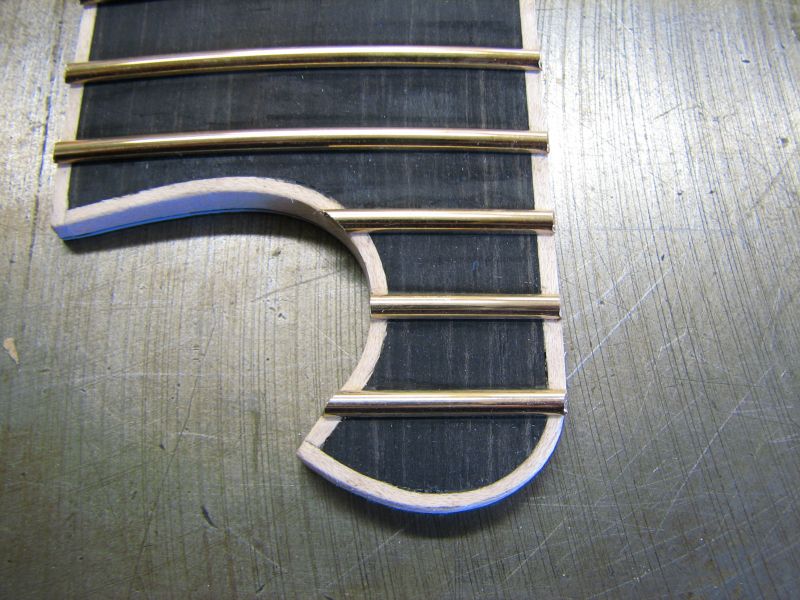

Fingerboard cut, slotted and bound.

& just sitting on the body to show the effect.

I press my frets in with the board off the neck and use the StewMac Fret Barber to size the tangs with just a few thou interference. Once all the frets are in the board has about 1 -1.5mm of bow on it and easily straightened with a minimum of downforce. For this build I decided to go with the EVO gold wire from LMI, seems harder that the standard nickel/silver wire but not as hard as Stainless.

Frets in but ends just squared off, chamfering will be done when I shape the neck.

I'm also going with a cantilevered overhang on the board (2mm gap at the neck/body join). I layed a couple of CF rods into the underside of the board with the intention of stiffening up this area, unfortunately it didn't end up being as stiff as I felt it needed to be so I've added a small packer on the underside where the UTB falls so it looks cantilevered but is supported by the upper transverse bar. Rather than gluing this spacer down to the top I'm going to put a cap screw in up through the UTB. If the neck ever needs to come off the cap screw can come out and the dovetail steamed in conventional methodology.The little spacer seems to be more than adequate to hold the board flat and rigid in my "PRESSure" tests so far

The spacer with an insert to take the 4mm cap screw

And a side shot showing the cantilever

& a couple of shots showing my 'Signature' headstock inlay, decided to keep with the gold theme and used Gold MOP.

The Burl veneer still likes to kick my arse from time to time and you can see the small chipout on the inner edge of the 'O' loop So I've mixed a little Imbuya dust with the epoxy, I was hoping to avoid this but... hopefully the colour match will be close and it won't show too much once I've dressed off the excess.

So I've mixed a little Imbuya dust with the epoxy, I was hoping to avoid this but... hopefully the colour match will be close and it won't show too much once I've dressed off the excess.

Epoxy's drying as we speak so I haven't got a picture of the finished inlay yet but I did take one in it's 'gloopy' best state

Will update the build once the neck's shaped and glued.

Hope people are still finding this build of interest?

Fingerboard cut, slotted and bound.

& just sitting on the body to show the effect.

I press my frets in with the board off the neck and use the StewMac Fret Barber to size the tangs with just a few thou interference. Once all the frets are in the board has about 1 -1.5mm of bow on it and easily straightened with a minimum of downforce. For this build I decided to go with the EVO gold wire from LMI, seems harder that the standard nickel/silver wire but not as hard as Stainless.

Frets in but ends just squared off, chamfering will be done when I shape the neck.

I'm also going with a cantilevered overhang on the board (2mm gap at the neck/body join). I layed a couple of CF rods into the underside of the board with the intention of stiffening up this area, unfortunately it didn't end up being as stiff as I felt it needed to be so I've added a small packer on the underside where the UTB falls so it looks cantilevered but is supported by the upper transverse bar. Rather than gluing this spacer down to the top I'm going to put a cap screw in up through the UTB. If the neck ever needs to come off the cap screw can come out and the dovetail steamed in conventional methodology.The little spacer seems to be more than adequate to hold the board flat and rigid in my "PRESSure" tests so far

The spacer with an insert to take the 4mm cap screw

And a side shot showing the cantilever

& a couple of shots showing my 'Signature' headstock inlay, decided to keep with the gold theme and used Gold MOP.

The Burl veneer still likes to kick my arse from time to time and you can see the small chipout on the inner edge of the 'O' loop

Epoxy's drying as we speak so I haven't got a picture of the finished inlay yet but I did take one in it's 'gloopy' best state

Will update the build once the neck's shaped and glued.

Hope people are still finding this build of interest?

"Jesus Loves You."

Nice to hear in church but not in a Mexican prison.

Nice to hear in church but not in a Mexican prison.

- Nick

- Blackwood

- Posts: 3628

- Joined: Thu Feb 26, 2009 11:20 am

- Location: Christchurch, New Zealand

- Contact:

Thanks guys.

Not sure Allen, it was never intended as a seller, it was meant to be a quick, cheap experimental build to scratch an itch I have but as it's progessed & has received more 'appointments' it has become a viable cashy (but depending on the sound of it of course!), but yeah you are right I'm adding more of 'me' to it so it may never leave my posession

Not sure Allen, it was never intended as a seller, it was meant to be a quick, cheap experimental build to scratch an itch I have but as it's progessed & has received more 'appointments' it has become a viable cashy (but depending on the sound of it of course!), but yeah you are right I'm adding more of 'me' to it so it may never leave my posession

"Jesus Loves You."

Nice to hear in church but not in a Mexican prison.

Nice to hear in church but not in a Mexican prison.

- Dennis Leahy

- Blackwood

- Posts: 872

- Joined: Wed Oct 10, 2007 12:32 am

- Location: Duluth, MN, US

- Contact:

- Nick

- Blackwood

- Posts: 3628

- Joined: Thu Feb 26, 2009 11:20 am

- Location: Christchurch, New Zealand

- Contact:

Lillian wrote:Aw geeze Dennis. You've done it now. Granted I agree with you, but did you have to say it out loud? Now his head won't fit into his shop.

Thanks Craig, would you believe I'm just making it up as I go along

"Jesus Loves You."

Nice to hear in church but not in a Mexican prison.

Nice to hear in church but not in a Mexican prison.

-

Paul B

- Nick

- Blackwood

- Posts: 3628

- Joined: Thu Feb 26, 2009 11:20 am

- Location: Christchurch, New Zealand

- Contact:

Necks on (or as my dear old mum refers to it.... "The handle") Woo Hoo! It's looking more like an axe now

I used a Stainless Cap screw to fix the fingerboard extension to the top (through the transverse brace).

(just incase you aren't familiar with a capscrew)

(just incase you aren't familiar with a capscrew)

But in order to get the head of the screw 'hidden' in the transverse brace meant counterboring the 4mm hole I put through from the top to allow the screw to sit below the surface. Easy when I have the brace in my hand and seperate from the top but it was already in place! So I had to make up a counterbore tool that I could pull up from the top. Fortunately metalwork is what I do for a real job so I made an adaptor for a commercial counterbore cutter (black item in the pic).

so I made an adaptor for a commercial counterbore cutter (black item in the pic).

and in use

Just ran the drill backwards and pulled up rather than pushing which felt strange as I'm so used to pushing to get things to cut! this cut the counterbore for the head to sit in so it was flush.

Just a few pics showing the neck shaped and glued in, the heel still needs a little shaping to "feel" right under my hand against the body.

Now I have the, nut, finish truss rod cover and the bridge to sort out and it will be ready for a coat of jam.

I was thinking of an adjustable bridge for this but didn't want to use the traditional thumbwheels Archtops use as this may 'thin' the tone somewhat, I liked the wedge style of adjustable bridge that is currently being used by a maker I cannot currently recall, but didn't want to copy him exactly (don't want to go breaking patents e.t.c ). Fortunately my copy of the latest GAL quarterly showed up and low & behold there was an article by Luis Mesquita showing how he did his wedge bridge, which was along a similar line I was thinking down so I may incorporate his system but with my own design aspect to it. I think (hope) my design will look abit 'sleeker' than Luis's design(no large thumbwheels)and plus it could avoid being accused of copying directly!

). Fortunately my copy of the latest GAL quarterly showed up and low & behold there was an article by Luis Mesquita showing how he did his wedge bridge, which was along a similar line I was thinking down so I may incorporate his system but with my own design aspect to it. I think (hope) my design will look abit 'sleeker' than Luis's design(no large thumbwheels)and plus it could avoid being accused of copying directly!

I used a Stainless Cap screw to fix the fingerboard extension to the top (through the transverse brace).

(just incase you aren't familiar with a capscrew)

(just incase you aren't familiar with a capscrew)But in order to get the head of the screw 'hidden' in the transverse brace meant counterboring the 4mm hole I put through from the top to allow the screw to sit below the surface. Easy when I have the brace in my hand and seperate from the top but it was already in place! So I had to make up a counterbore tool that I could pull up from the top. Fortunately metalwork is what I do for a real job

and in use

Just ran the drill backwards and pulled up rather than pushing which felt strange as I'm so used to pushing to get things to cut! this cut the counterbore for the head to sit in so it was flush.

Just a few pics showing the neck shaped and glued in, the heel still needs a little shaping to "feel" right under my hand against the body.

Now I have the, nut, finish truss rod cover and the bridge to sort out and it will be ready for a coat of jam.

I was thinking of an adjustable bridge for this but didn't want to use the traditional thumbwheels Archtops use as this may 'thin' the tone somewhat, I liked the wedge style of adjustable bridge that is currently being used by a maker I cannot currently recall, but didn't want to copy him exactly (don't want to go breaking patents e.t.c

"Jesus Loves You."

Nice to hear in church but not in a Mexican prison.

Nice to hear in church but not in a Mexican prison.

- John Steele

- Blackwood

- Posts: 155

- Joined: Fri Mar 06, 2009 4:58 pm

- Location: Wilson, NY. 14172

- Contact:

Great work Nicko.

I drill holes in the neck block for my neck attachment after assembling the body and face the same counter bore issue as you. It looks much nicer looking through the sound hole if the flat head bolts are set into the neck block a bit.

I ended up finding part of a pen making kit from Woodcraft (read about it somewhere) which does that same thing as your bit but is not nearly as cool because I didn't make it myself.

Cheers

Dom

I drill holes in the neck block for my neck attachment after assembling the body and face the same counter bore issue as you. It looks much nicer looking through the sound hole if the flat head bolts are set into the neck block a bit.

I ended up finding part of a pen making kit from Woodcraft (read about it somewhere) which does that same thing as your bit but is not nearly as cool because I didn't make it myself.

Cheers

Dom

You can bomb the world to pieces,

but you can't bomb the world to peace!

but you can't bomb the world to peace!

- Nick

- Blackwood

- Posts: 3628

- Joined: Thu Feb 26, 2009 11:20 am

- Location: Christchurch, New Zealand

- Contact:

John, the counterbore has a 4mm hole up it's centre and is designed to have different sized pilots fitted. The large 'collar' on the end I made to fit the shank of the counterbore and has a 4mm hole up it's centre also. I just pre-drilled a 4.5mm clearance hole through the top and brace (in the right position!) and made my own pilot with a 4mm at one end (held into the collar with a grub screw onto the 4mm shaft) & a 4.5mm at the other, this then guided the counterbore concentric to the pre-drilled hole. Hope this made sense?

"Jesus Loves You."

Nice to hear in church but not in a Mexican prison.

Nice to hear in church but not in a Mexican prison.

- Nick

- Blackwood

- Posts: 3628

- Joined: Thu Feb 26, 2009 11:20 am

- Location: Christchurch, New Zealand

- Contact:

Thanks Craig, I have seen the wedge bridge before & Howard Klepper rings a bell, the link would be much appreciated. As for your request, I'm afraid I can't stopCraig wrote:Nick , I think the wedged bridge you're thinking of is Howard Klepper . I'll see if I can get a link . He once said it was his favorite playing guitar.

This guitar of yours is looking absolutley awesome Nick . Could you please just Stop,,,,,,,

"Jesus Loves You."

Nice to hear in church but not in a Mexican prison.

Nice to hear in church but not in a Mexican prison.

I'm pretty sure Klepper didn't come up with the concept of the wedge bridge design originally, I have seen a number of 'contemporary' archtops that use variations of it. I believe D'aquisto was among, if not the first to use it. Brekke mandolin bridges use a slightly different wedge design, check out Webber mandolins, I don't know how something like that would work on a guitar.

Arnt Rian,

Norway

Norway

- Nick

- Blackwood

- Posts: 3628

- Joined: Thu Feb 26, 2009 11:20 am

- Location: Christchurch, New Zealand

- Contact:

Thanks Craig an Arnt, gives me some more avenues to look down before finally 'nailing' the design.

Lillian, I didn't need to 'manufacture' mine, just did it because I can Although I was restricted by the room I had to work with inside the box so even a shop bought reverse spot facer would have had to undergo some Oliver surgery.

Although I was restricted by the room I had to work with inside the box so even a shop bought reverse spot facer would have had to undergo some Oliver surgery.

Lillian, I didn't need to 'manufacture' mine, just did it because I can

"Jesus Loves You."

Nice to hear in church but not in a Mexican prison.

Nice to hear in church but not in a Mexican prison.

Who is online

Users browsing this forum: No registered users and 64 guests