Martin,

Colin told me that on the old lutes he's examined, nearly all of them have the bottom two ribs next to the soundboard a different size to the others. I think we tend to get too anal about plans and precise measurements, the old guys used their eyes and hand skills and corrected/adapted as they went. I've seen a couple of threads on other forums where builders have been lost as how to shape sides for tops and backs without the comfort of a nice "ball shaped" sanding dish. The answer is you use your eyes, some chalk, a sharp plane and make it fit. In that way I found making the lute liberating and I hope you do too.

Mind you, get a big swear box as the last two ribs on each side took me over a week to fit correctly. It was basically make a card template that fit the gap and use that and a lot of patience - plus the old chestnut of you can take wood off but it's harder to put it back

You'll be fine with the hide glue - the ribs when you've planed (sanded

) them for fit are just rub joints, and if you aren't quite fast enough, then running a hairdryer over the joint will re-melt the glue and let it set with the ribs joined. What seems like a very fragile construction becomes surprisingly strong when all the ribs are glued and the inside joints covered with silk or paper covered in hide glue.

I know some people diss the baby bottle warmer but they work perfectly well and for £10 versus £150 to me it's a no brainer. The old lute makers didn't use thermostatically controlled glue pots forsooth.

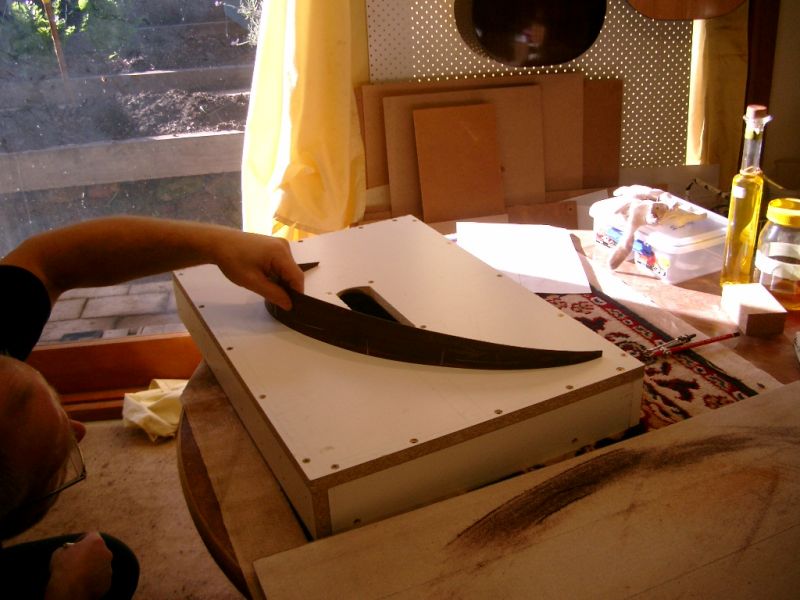

The new mold looks great and I'm looking forward to seeing it get filled up with ribs.