rookie mistake?

rookie mistake?

hi all. long time listener, first time caller.

i've managed to get about half way through my first build thanks to the wisdom of the internet (ie you guys) and allen here in cairns but am having a bear of a time bending my bindings.

i've got 2mm thick strips of new guinea rosewood but i must have snapped 6 of them bending then on the tip of a heatgun. i'm sure i read somewhere of it being done before.

i bent the tas. oak sides on a hot pipe easier and they were 150mm wide.

so i'm thinking its got to be the wood, heatgun technique or me?

i've managed to get about half way through my first build thanks to the wisdom of the internet (ie you guys) and allen here in cairns but am having a bear of a time bending my bindings.

i've got 2mm thick strips of new guinea rosewood but i must have snapped 6 of them bending then on the tip of a heatgun. i'm sure i read somewhere of it being done before.

i bent the tas. oak sides on a hot pipe easier and they were 150mm wide.

so i'm thinking its got to be the wood, heatgun technique or me?

- sebastiaan56

- Blackwood

- Posts: 1274

- Joined: Sun Oct 28, 2007 5:23 am

- Location: Blue Mountains

- Mark McLean

- Blackwood

- Posts: 1174

- Joined: Thu Apr 10, 2008 2:03 pm

- Location: Sydney

I don't know about that timber, and I do it on a bending iron. But in my limited experience with cocobolo, mahogany and koa I have found it best to tape all 4 of your bindings together and bend them in one go. When I try one at a time they snap like twigs. Lay all 4 on the bench. If they have purfling strips attached put them in mirrored pairs (one up - one down), then tape around the 4 of them at 4 or 5 points. They are a bit stronger that way, and you get an identical bend in each. Support them with a piece of sheet metal behind the side you are bending and keep your hands close to the bending point. Even then, you will waste some.

cheers, Mark

cheers, Mark

-

vandenboom

- Blackwood

- Posts: 414

- Joined: Sun Oct 26, 2008 2:27 pm

- Location: Melbourne (Ringwood), Australia

I also don't have NGR experience with bindings, but recently had the same experience with Wenge bindings on a hot pipe. I broke about 5 of them. Another attempt would be almost finished, and then "snap" - not necessarily on the tight curves either.

I succeeded in the end after introducing the metal support strip, as Mark suggested, as well as keeping them under 2mm thick.

Frank

I succeeded in the end after introducing the metal support strip, as Mark suggested, as well as keeping them under 2mm thick.

Frank

allen i really appreciate the offer of the electric pipe but am in the brainstorming stage of building one from scatch. the commercial units couldn't contain anything i don't deal with often at work (element+control+pipe=hot pipe). surely. just need to know the wattage of the commercial units if anyone can help. much appreciated.

- J.F. Custom

- Blackwood

- Posts: 778

- Joined: Fri May 01, 2009 9:13 pm

- Location: Brisbane

- Contact:

Hi Liam and welcome.

I believe Mark meant side by side, not stacked, and it is sound advice. Laying them side by side will provide more support overall and avoid them twisting in the bending process which could be causing you issues - particularly if there is grain run out. Are your pieces of NGR 1/4 sawn? Are you using any moisture? Laying them out will also provide more 'feedback' for the hands of a new bender - less chance of applying to much pressure too quickly. Also, definitely go with the backing support in the form of stainless sheet or other. Both of these tips should aid your bending process. A bending blanket and mould would help too but there is no reason you shouldn't be able to achieve good results on a bending iron.

Good luck.

Jeremy.

I believe Mark meant side by side, not stacked, and it is sound advice. Laying them side by side will provide more support overall and avoid them twisting in the bending process which could be causing you issues - particularly if there is grain run out. Are your pieces of NGR 1/4 sawn? Are you using any moisture? Laying them out will also provide more 'feedback' for the hands of a new bender - less chance of applying to much pressure too quickly. Also, definitely go with the backing support in the form of stainless sheet or other. Both of these tips should aid your bending process. A bending blanket and mould would help too but there is no reason you shouldn't be able to achieve good results on a bending iron.

Good luck.

Jeremy.

- Taffy Evans

- Blackwood

- Posts: 1076

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

Hi Liam, and welcome.

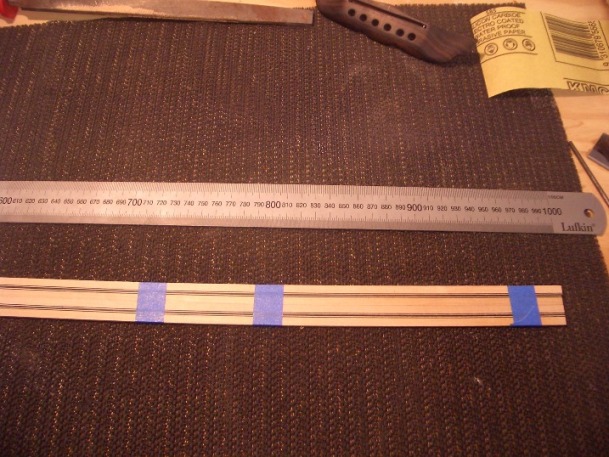

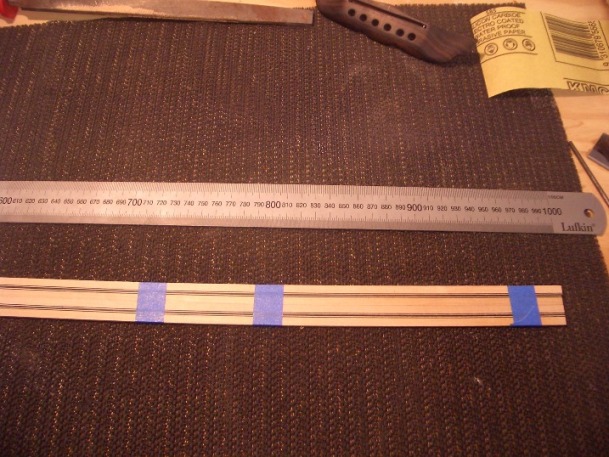

I just went out to the workshop and bent the 2mm NGR binding in these photos.

I find it best to have heaps of steam, something on the iron to hold water helps. Also use a strip of steel or aluminum on the outside of the bend. Then in the form and let them dry, I'm giving it a hurry up with a small blow heater here, took me longer to find the bending pipe than do the bending good luck

I just went out to the workshop and bent the 2mm NGR binding in these photos.

I find it best to have heaps of steam, something on the iron to hold water helps. Also use a strip of steel or aluminum on the outside of the bend. Then in the form and let them dry, I'm giving it a hurry up with a small blow heater here, took me longer to find the bending pipe than do the bending good luck

Taff

Hi Liam

Just so you know that it's not you, tonight I broke 8 off quarter PNG rosewood bindings to get 4 good ones. The only other timber I've had this much trouble with is South American rosewood. In both cases it was offcuts from sides that bent really well. I bend on a hot pipe and success came from wetting the strips a few times, taking it slow and having the pipe a bit hotter than usual. Most of those I broke were near the same spot on the lower bout (not the waist as you would expect), there didn't seem to be any visible flaw in the timber but i figure it must have a brittle spot.

Good luck... enjoy the learning curve, it's a good one.

James

Just so you know that it's not you, tonight I broke 8 off quarter PNG rosewood bindings to get 4 good ones. The only other timber I've had this much trouble with is South American rosewood. In both cases it was offcuts from sides that bent really well. I bend on a hot pipe and success came from wetting the strips a few times, taking it slow and having the pipe a bit hotter than usual. Most of those I broke were near the same spot on the lower bout (not the waist as you would expect), there didn't seem to be any visible flaw in the timber but i figure it must have a brittle spot.

Good luck... enjoy the learning curve, it's a good one.

James

- Mark McLean

- Blackwood

- Posts: 1174

- Joined: Thu Apr 10, 2008 2:03 pm

- Location: Sydney

Sorry, I should have been clearer in my description. I did mean stacking them. If you have strips of 2mm thick and 6mm high it will be a stack of 2mm X 24mm. That way they all get exposure to the same heat but the increased bulk is a bit stiffer - it makes you slow down and avoid over flexing them. With sheetmetal backing it is also much less likely to snap.

- J.F. Custom

- Blackwood

- Posts: 778

- Joined: Fri May 01, 2009 9:13 pm

- Location: Brisbane

- Contact:

Heh - now I'm confused!

Mark - when you say you did mean 'stacked'; you mean 2mm x 6mm bindings by four of = 2mm x 24mm? If so, this is what I meant by laid side to side. Almost a miniature version of a side itself with which my previous comments apply.

I made this distinction as I believed Liam thought by 'stacked' you meant 6mm x 8mm thick (2mm x 4 on top of each other - 'stacked') if you get me, which would be very difficult to bend and produce bindings with different profiles even if you could.

Just clarifying for myself and potentially Liam...

Cheers,

Jeremy.

Mark - when you say you did mean 'stacked'; you mean 2mm x 6mm bindings by four of = 2mm x 24mm? If so, this is what I meant by laid side to side. Almost a miniature version of a side itself with which my previous comments apply.

I made this distinction as I believed Liam thought by 'stacked' you meant 6mm x 8mm thick (2mm x 4 on top of each other - 'stacked') if you get me, which would be very difficult to bend and produce bindings with different profiles even if you could.

Just clarifying for myself and potentially Liam...

Cheers,

Jeremy.

- Mark McLean

- Blackwood

- Posts: 1174

- Joined: Thu Apr 10, 2008 2:03 pm

- Location: Sydney

Sorry Jeremy. We mean the same thing but we are using different words. Here is a picture just to be sure. These are maple with BWB purfling. If you arrange them like this you will get the right orientation of the strips after bending. I put two strips of tape close together on either side of the area that will take the waist bend to be sure to keep them together. I also find that some of these strips bend like a banana when you store them separately. Storing them in bunches like this will keep them straight.

- Taffy Evans

- Blackwood

- Posts: 1076

- Joined: Wed Apr 30, 2008 6:54 pm

- Location: Charters Towers North Queensland

-

Paul B

I've used NGR for bindings, I probably lost 1/4 of them to breakage during bending. It's really just a matter of looking at the grain, they don't bend if there's any grain runout, they snap.

Other than that, plenty of heat and steam. Put them all side by side, wet them with a sponge and wrap with foil.

Other than that, plenty of heat and steam. Put them all side by side, wet them with a sponge and wrap with foil.

cheers guys i'm extremely lucky to have an industrial workshop at work inc full sheetmetal shop for the aircon ductworker blokes so can get off cuts of all the good stuff.

no woodwork shop though so have to wait til wk end to get to the woodwork club to cut new bindings (will cut mucho spares this time).

all the photos and advice have made things crystal and so i'm confident i'll have the box done this wk end.

i have to say i'm blown away at the response, to think people would go and do it just to take photos to show me how to do it. its a real little community going on here. nice

no woodwork shop though so have to wait til wk end to get to the woodwork club to cut new bindings (will cut mucho spares this time).

all the photos and advice have made things crystal and so i'm confident i'll have the box done this wk end.

i have to say i'm blown away at the response, to think people would go and do it just to take photos to show me how to do it. its a real little community going on here. nice

Guess that's what it's all about Liam.

Besides, who else will listen to us?

work colleagues hear "....blah, bridge, blah, strings, blah, nut, blah..."

wives hear "....blah, blah, blah, neck, blah, blah blah..."

kids hear "....blah, blah, blah, blah, blah, blah, blah..."

kids say "just shut up & go the shed dad"

Besides, who else will listen to us?

work colleagues hear "....blah, bridge, blah, strings, blah, nut, blah..."

wives hear "....blah, blah, blah, neck, blah, blah blah..."

kids hear "....blah, blah, blah, blah, blah, blah, blah..."

kids say "just shut up & go the shed dad"

Craig Clancy wrote:Guess that's what it's all about Liam.

Besides, who else will listen to us?

work colleagues hear "....blah, bridge, blah, strings, blah, nut, blah..."

wives hear "....blah, blah, blah, neck, blah, blah blah..."

kids hear "....blah, blah, blah, blah, blah, blah, blah..."

kids say "just shut up & go the shed dad"

I know of this well

U'r a good bunch.

Who is online

Users browsing this forum: Google, Joshyouare and 51 guests