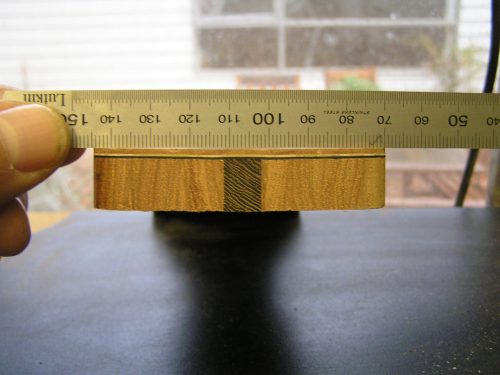

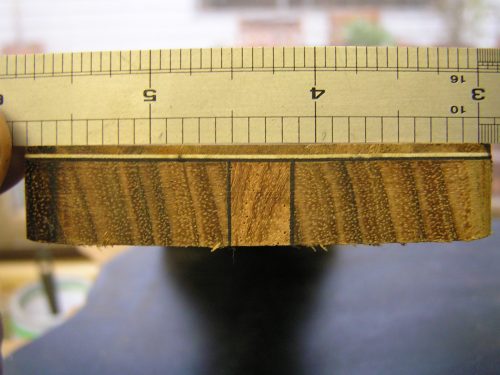

The left shaft is Fijian Mahogany with a Wenge strip up the middle - the cupping is more severe in this case.

The right shaft is Blackwood with Silver Wattle strip up middle.

I imagine the thin veneers are responsible for curling the edges up. Does the laminated strip up the centre of the shaft create more weakness across this direction than a single piece of wood, or do you think there is something else going on.

I'm not sure what to do about it - whether to remove the veneers, reflatten it and apply something different, or apply it in a different way. I don't like removing wood in these situations as I often seem to cause some form of other irreversible damage!!

Thoughts appreciated....

Thanks. Frank.