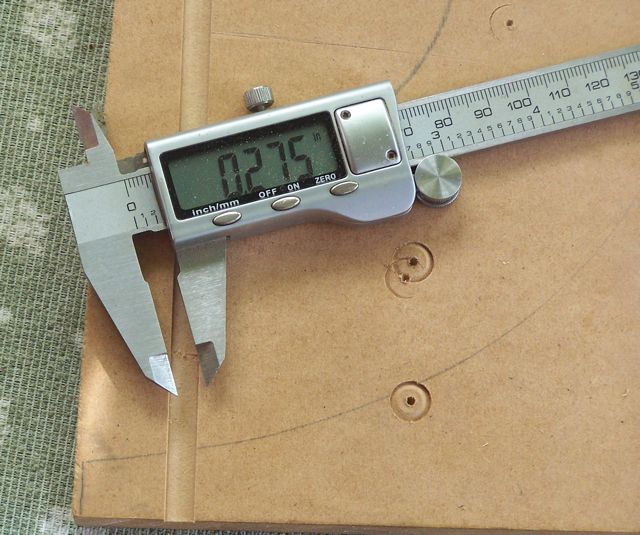

First up, I cut a test dado in some scrap to determine the exact width of cut.

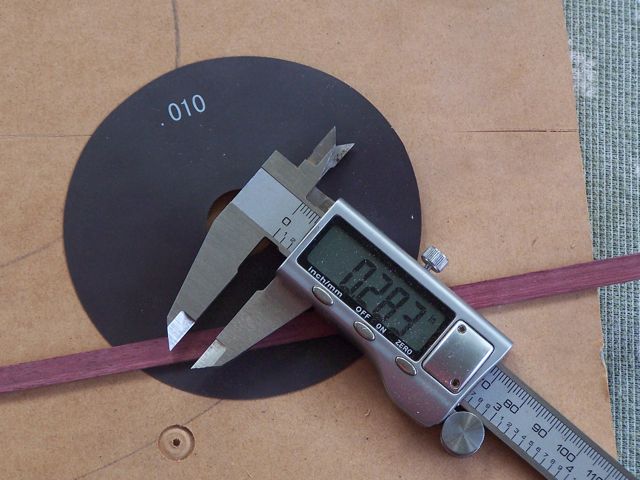

Then I measure the back strip to be inlayed. You can see that there is a difference of .008 between the dado that has been cut and the one required. So I pull out a .010 dado shim to add to the stack. This will give .002 extra. Just enough for a snug fit.

Make another test cut, adjusting for depth of cut as well, and do a trial fit. The dado you can see at the top of the image was the original that was too narrow. The back strip is inlayed into the correct sized dado in the scrap test piece.

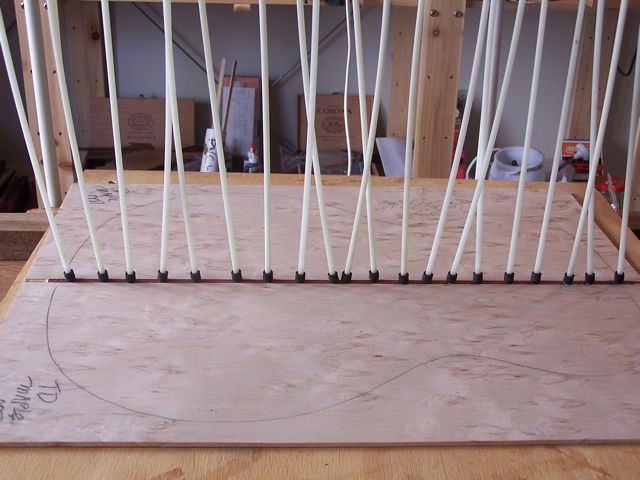

Line up the center of the back with the center of the dado blades.

[EDIT] I should have mentioned to set the rip fence so that the cut can be made accurately.

Then make your cut.

Glue up and clamp with your preferred method.

Finish sanded, ready for bracing.

The whole operation took far longer to photograph than the actual work. The beauty of using the shims is that they are so accurate, that it takes all the guess work out of the process.