New Luthier Tips du Jour Video - Vacuum Fixtures

-

Robbie O'Brien

- ANZLF Approved Supplier

- Posts: 371

- Joined: Mon Jun 30, 2008 11:32 am

- Location: Parker, Colorado USA

- Contact:

New Luthier Tips du Jour Video - Vacuum Fixtures

The latest Luthier Tips du Jour video is on the air. The topic is Vacuum Fixtures. I discuss the use of vacuum in the shop and show a couple of fixtures I use in my shop.

As always, comments and discussion are invited.

Enjoy!

youtu.be/

As always, comments and discussion are invited.

Enjoy!

youtu.be/

www.obrienguitars.com

- sebastiaan56

- Blackwood

- Posts: 1274

- Joined: Sun Oct 28, 2007 5:23 am

- Location: Blue Mountains

-

Robbie O'Brien

- ANZLF Approved Supplier

- Posts: 371

- Joined: Mon Jun 30, 2008 11:32 am

- Location: Parker, Colorado USA

- Contact:

- Mark McLean

- Blackwood

- Posts: 1174

- Joined: Thu Apr 10, 2008 2:03 pm

- Location: Sydney

-

Robbie O'Brien

- ANZLF Approved Supplier

- Posts: 371

- Joined: Mon Jun 30, 2008 11:32 am

- Location: Parker, Colorado USA

- Contact:

Mark,

The hold down clamp and the bridge clamp are both LMI products. I worked for years without vacuum in my shop. When I added it I loved it and still find more and more ways to use the hold down fixture. Once you put vacuum in your shop you start thinking of jigs you can easily make yourself to do things. I didn't even go into this side of things in the video.

Sure you can work without vacuum but it sure is nice to have it.

The hold down clamp and the bridge clamp are both LMI products. I worked for years without vacuum in my shop. When I added it I loved it and still find more and more ways to use the hold down fixture. Once you put vacuum in your shop you start thinking of jigs you can easily make yourself to do things. I didn't even go into this side of things in the video.

Sure you can work without vacuum but it sure is nice to have it.

www.obrienguitars.com

- hilo_kawika

- Blackwood

- Posts: 144

- Joined: Mon Oct 13, 2008 10:29 am

- Location: Hilo, Hawaii

- Contact:

Mark,

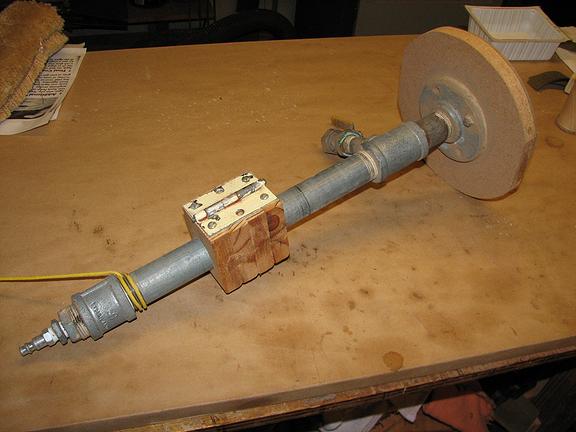

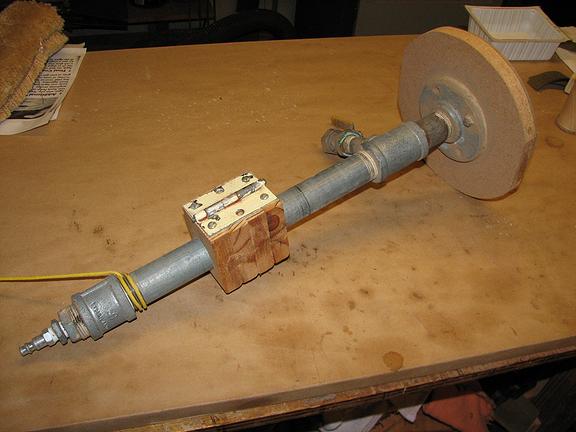

Here's an inexpensive version of the rotating vacuum clamp that I used many years ago.

As you can see, it's made mostly out of galvanized pipe and leftover fittings from my plumbing packrat box. The quick disconnect fitting at the bottom is from the auto parts store and leads to the vacuum source. A gas line valve opens and closes the system to the atmosphere. The wooden hinged thingie on the pipe goes into a vice wherein slight loosening of the vice allows for easy rotation of the device. The main pad comes from discarded mdf sink cutouts and the foam tape is closed cell weather stripping, again from the hardware store. I had many instrument-shaped plates that could be placed against the vacuum surface for different sized ukuleles. I think the vacuum system is ok, and LMI's version quite elegant but in the end I switched back to more traditional clamping systems. To each, his own...

aloha,

Dave Hurd

Here's an inexpensive version of the rotating vacuum clamp that I used many years ago.

As you can see, it's made mostly out of galvanized pipe and leftover fittings from my plumbing packrat box. The quick disconnect fitting at the bottom is from the auto parts store and leads to the vacuum source. A gas line valve opens and closes the system to the atmosphere. The wooden hinged thingie on the pipe goes into a vice wherein slight loosening of the vice allows for easy rotation of the device. The main pad comes from discarded mdf sink cutouts and the foam tape is closed cell weather stripping, again from the hardware store. I had many instrument-shaped plates that could be placed against the vacuum surface for different sized ukuleles. I think the vacuum system is ok, and LMI's version quite elegant but in the end I switched back to more traditional clamping systems. To each, his own...

aloha,

Dave Hurd

How to become a millionaire? Start with $2 million and become a luthier...

- hilo_kawika

- Blackwood

- Posts: 144

- Joined: Mon Oct 13, 2008 10:29 am

- Location: Hilo, Hawaii

- Contact:

Robbie,

With respect to the LMI vacuum bridge clamping jig I would like to suggest that it's the amount of clamping pressure on the bridge rather than the total area of the jig that's the important number.

1 inch Hg ~0.5 psi (pounds per square inch)

19 inches Hg ~ 9.5 psi (your vacuum pressure in the video)

Let's say that your classical guitar bridge has an area of 6 square inches.

So, 6 sq in. X 9.5 psi = 57 lbs pressure on the bridge rather than the 228 lbs for the whole area calculated in the video. This amount of pressure should be sufficient assuming a perfect fit of the bridge under surface to the guitar top, which I also assume to be the case for your work. If there are any discrepancies in the fit however, the ~9.5 psi pressure may not be enough to clamp things properly.

aloha,

Dave Hurd

With respect to the LMI vacuum bridge clamping jig I would like to suggest that it's the amount of clamping pressure on the bridge rather than the total area of the jig that's the important number.

1 inch Hg ~0.5 psi (pounds per square inch)

19 inches Hg ~ 9.5 psi (your vacuum pressure in the video)

Let's say that your classical guitar bridge has an area of 6 square inches.

So, 6 sq in. X 9.5 psi = 57 lbs pressure on the bridge rather than the 228 lbs for the whole area calculated in the video. This amount of pressure should be sufficient assuming a perfect fit of the bridge under surface to the guitar top, which I also assume to be the case for your work. If there are any discrepancies in the fit however, the ~9.5 psi pressure may not be enough to clamp things properly.

aloha,

Dave Hurd

How to become a millionaire? Start with $2 million and become a luthier...

-

Robbie O'Brien

- ANZLF Approved Supplier

- Posts: 371

- Joined: Mon Jun 30, 2008 11:32 am

- Location: Parker, Colorado USA

- Contact:

Who is online

Users browsing this forum: No registered users and 108 guests