any ideas on reversing cupping???

- needsmorecowbel

- Blackwood

- Posts: 974

- Joined: Sun Oct 04, 2009 7:48 pm

- Location: Melbourne

any ideas on reversing cupping???

Would it be a horrible horrible idea to try and correct the cup in a piece of timber by attempting to use steam and then weight to get a piece of timber back or at least closer to flat. I purchased some fairly pricy wood from the states a while back and the wood was seemingly not properly dried (one of those cases where one should invest in a moisture meter).

I have been scouring the web and talking to a few people so far I have a few ideas some fairly ridiculous and perhaps over the top.

1. I work in a kitchen...they have a steam convection oven and later in the year they are closing the kitchen for renovation. I could chuck it in the steam oven at temperature with steam, remove it from the oven and place it on stickers in a small wood storage rack with threaded rod and wingnuts and tighten the hell out of the nuts, paint/ wax the ends the next day and wait a few months for the timber to dry properly under the pressure of the rack.

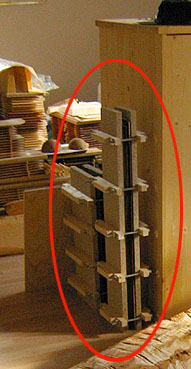

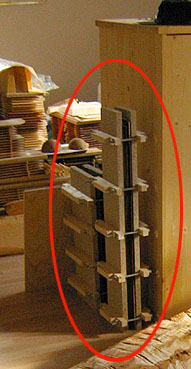

The rack would look something like Bob's phpBB2/userpix/2_IMG_1607_Medium_1.jpg

2. A woodworking forum suggested on a hot day placing the piece of wood on some moist grass with the more wet side facing the hot sun. Keeping the wood supervised until it appears to have flattened out and reached some kind of equilibrium....

3. Wait until the piece of timber stops cupping (say 8 months- 12 months it is only 11mm thick) then sand the cup out and resaw leaving me with 1/2 the desired wood...

4....A better Idea?

Stu

I have been scouring the web and talking to a few people so far I have a few ideas some fairly ridiculous and perhaps over the top.

1. I work in a kitchen...they have a steam convection oven and later in the year they are closing the kitchen for renovation. I could chuck it in the steam oven at temperature with steam, remove it from the oven and place it on stickers in a small wood storage rack with threaded rod and wingnuts and tighten the hell out of the nuts, paint/ wax the ends the next day and wait a few months for the timber to dry properly under the pressure of the rack.

The rack would look something like Bob's phpBB2/userpix/2_IMG_1607_Medium_1.jpg

2. A woodworking forum suggested on a hot day placing the piece of wood on some moist grass with the more wet side facing the hot sun. Keeping the wood supervised until it appears to have flattened out and reached some kind of equilibrium....

3. Wait until the piece of timber stops cupping (say 8 months- 12 months it is only 11mm thick) then sand the cup out and resaw leaving me with 1/2 the desired wood...

4....A better Idea?

Stu

- charangohabsburg

- Blackwood

- Posts: 1818

- Joined: Sat Oct 16, 2010 1:25 am

- Location: Switzerland

Re: any ideas on reversing cupping???

Hi Stu, if your timber is not "too" thick your steamer idea sounds good to me, where the threshold of "too" will depend on the power of your wood press. In addition, I would only sticker the wood until it feels dry (one day or even less, just to avoid mould), then leave it pressed for an year or so without stickers and without ever opening the stack to look if the wood holds its shape.

Just let time and remaining humidity work. Then sticker it again (still pressed) until you use it. It worked for me, although I only moistened the wood by wiping on a bit of water with my hand. It was some +/- freshly cut flat sawn rosewood an quartered zebrano B/S which minutes after unpacking twisted like hell.

Just let time and remaining humidity work. Then sticker it again (still pressed) until you use it. It worked for me, although I only moistened the wood by wiping on a bit of water with my hand. It was some +/- freshly cut flat sawn rosewood an quartered zebrano B/S which minutes after unpacking twisted like hell.

Markus

To be stupid is like to be dead. Oneself will not be aware of it.

It's only the others who suffer.

To be stupid is like to be dead. Oneself will not be aware of it.

It's only the others who suffer.

Re: any ideas on reversing cupping???

Stu, It doesn't even have to be moist . Something as thin as a top/ back really wants looking at every 2-3 min.

Most times it will work.

Most times it will work.

"Were you drying your nails or waving me good bye?" Tom Waits

Bill

Bill

Re: any ideas on reversing cupping???

I forgot to say " In direct sunlight".

"Were you drying your nails or waving me good bye?" Tom Waits

Bill

Bill

- needsmorecowbel

- Blackwood

- Posts: 974

- Joined: Sun Oct 04, 2009 7:48 pm

- Location: Melbourne

Re: any ideas on reversing cupping???

Cheers for the response guys. The pieces of ziricote in question are around 11-12 mm. I planned to use them as a single electric drop top (rather thick I know) but the cup is quite bad. I am thinking this thickness lies is in the category of not too thick (for steaming that is) I may also try the sunlight method first to see how this goes. Should I be setting the steam oven to a temperature of around 115 - 125 degrees celcius?

- charangohabsburg

- Blackwood

- Posts: 1818

- Joined: Sat Oct 16, 2010 1:25 am

- Location: Switzerland

Re: any ideas on reversing cupping???

I don't know. But those who steam bend wood for furniture (chairs, etc.) generally don't use steam under pressure which means the "steam" is a bit less hot than 100°C. Steaming time may be more important, but as I never have done it I can not say how long it will take to penetrate 12mm thick Ziricote. I'd be careful with steam temperature which I think might affect colour more likely the higher you go.needsmorecowbel wrote: Should I be setting the steam oven to a temperature of around 115 - 125 degrees celcius?

Markus

To be stupid is like to be dead. Oneself will not be aware of it.

It's only the others who suffer.

To be stupid is like to be dead. Oneself will not be aware of it.

It's only the others who suffer.

-

Mark Fogleman

- Beefwood

- Posts: 27

- Joined: Mon Mar 21, 2011 2:47 am

- Location: Charlotte

Re: any ideas on reversing cupping???

I have corrected cupping by placing cupped boards (concave side down) in the sun and on the lawn for a morning. If you're in a temperate climate there is enough condensation on the grass and heat by the sun to slowly expand the cup. Sunlight can darken some woods so proceed with caution. Once your wood is flat, sticker and weigh it down or apply ratchet straps so it will stay flat.

- needsmorecowbel

- Blackwood

- Posts: 974

- Joined: Sun Oct 04, 2009 7:48 pm

- Location: Melbourne

Re: any ideas on reversing cupping???

Ended up going with the steaming option after trying to correct the cup by placing it in the sun for short periods. Put it in for 40 minutes in the steamer at 100 degrees C. Then had a cheap $10 Kmart Pan full of wax. Dipped the ends in wax straight out of the steamer and had it all clamped up and stickered within two mins. I replaced the clamps a day later with weights and it doesn't seem to be moving much. Will report back in a year on the findings (after resawing)

Stu

Stu

Re: any ideas on reversing cupping???

In the past I've wet down a stretch of concrete in the shed, it takes up water quite well but you do need to mop it over a few times to get it wicking. Once its wet through it will give the moisture up in a slow and controlled way. Lay the board down convex side up and leave it there until it comes back.

On another note you need to be careful placing some woods in direct sunlight, it can check real quick. Jarrah is one Iv'e seen open up within the hour on a hot WA day...The wood was sold by a 'large' wholesaler/retailer to a trade business as seasoned (kiln dried) BTW.

(I'm sure I've seen those wood presses somewhere else??)

Cheers

Kim

On another note you need to be careful placing some woods in direct sunlight, it can check real quick. Jarrah is one Iv'e seen open up within the hour on a hot WA day...The wood was sold by a 'large' wholesaler/retailer to a trade business as seasoned (kiln dried) BTW.

(I'm sure I've seen those wood presses somewhere else??)

Cheers

Kim

Who is online

Users browsing this forum: No registered users and 97 guests