As most cleats I find in already repaired guitars and charangos are considerably thicker than those I make (mine are about 0.4 to 0.5 mm), I thought it could be interesting for some to see how I make thin (= light) and strong repair cleats. Not too long ago I mentioned here that I care a lot about close to perfect fiber direction within a cleat.

A piece of top wood with this kind of runout will not do the trick: When there is no wood available to split, when only needing short pieces (like cleats), adjusting the wood surface to the wood fiber direction can be done quite easily with a block plane:

The green lines show how I adjusted the surface of this piece of spruce to the fibre direction. The upper picture shows the starting stage of planing, the lower picture shows the two surfaces already almost established.

To hold such thin and small pieces in place when planing them requires something else than a bench stop. I lay the piece on sanding paper (180 grit works great), flanked by two paper strips to protect the plane sole. Like this I can get the wood strip down to 0.2 mm if I want, but generally something between 0.4 and 0.5 mm is just fine.

Then I lay out the cleats on the thicknessed spruce strip, cut and plane the strip to its final width...

...and finally cut the cleats with a chisel:

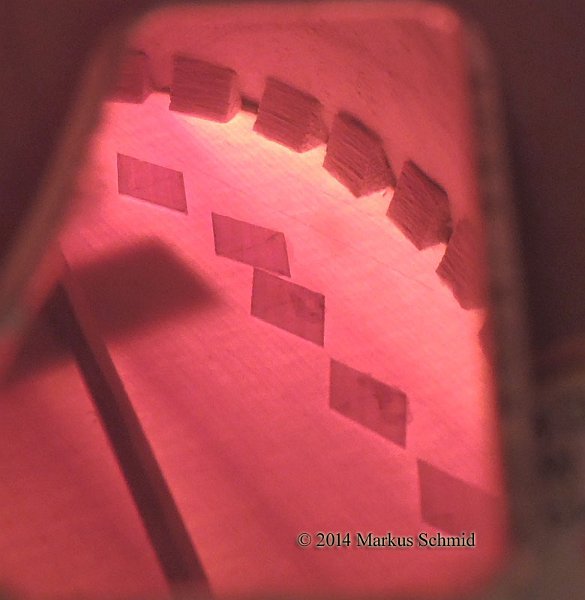

Those thin cleats inside the instrument look like this:

...yes, I messed up the 2nd cleat from the left

Thanks for watching.

(If you want, here you can see two or three additional photos and text.)