Ebony Bindings

Ebony Bindings

Hi Guys,

Does anybody know of a source of ebony bindings in Australia? I have just received an order of other stuff from LMI but they were out of stock. Don't relish the idea of paying US postage again just for some binding.

Cheers.

Does anybody know of a source of ebony bindings in Australia? I have just received an order of other stuff from LMI but they were out of stock. Don't relish the idea of paying US postage again just for some binding.

Cheers.

Jeremy D

Re: Ebony Bindings

Tim Spittle the universe's greatest tonewood supplier might have some..Jeremy D wrote:Hi Guys,

Does anybody know of a source of ebony bindings in Australia? I have just received an order of other stuff from LMI but they were out of stock. Don't relish the idea of paying US postage again just for some binding.

Cheers.

Martin

Re: Ebony Bindings

Hey Jeremy,Jeremy D wrote:Hi Guys,

Does anybody know of a source of ebony bindings in Australia? I have just received an order of other stuff from LMI but they were out of stock. Don't relish the idea of paying US postage again just for some binding.

Cheers.

In this situation I would advise using black abs plastic. Not because I'm cheap, but because it is a superior product for the task at hand.

Bindings have four main purposes, to seal end grain, to strengthen the joint between back/top and sides, to protect the instrument from the usual knocks and bumps, and, to look good.

ABS plastic does not absorb moisture. With the correct glue, it bonds as well as wood to strengthen the joint. It's softer and more resilient than ebony and therefore, absorbs impact to protect much better than any wood, and, if you bind one guitar in top grade rich dark ebony, and another in ABS and hold them side by side once the finish is on, you would be hard pushed to tell one from the other.

Also, ABS is easy to apply and can be purchased in length to go completely around a guitar in one hit avoiding the need for a joint at the tail. ABS is easy to cut and does so more predictably than ebony so mitre joints are more likely to be crisp, it requires no heat for bending, holds easily in place for gluing, 'and' it's cheap as chips.

Re: Ebony Bindings

Why didn't I think of that!Tim Spittle the universe's greatest tonewood supplier might have some..

Thanks Wayne, I checked their website but didn't think to contact them directly.Gerard Gilet in Botany, Guitar Woods.

Thanks Kim,Hey Jeremy,

In this situation I would advise using black abs plastic. Not because I'm cheap, but because it is a superior product for the task at hand.

Bindings have four main purposes, to seal end grain, to strengthen the joint between back/top and sides, to protect the instrument from the usual knocks and bumps, and, to look good.

ABS plastic does not absorb moisture. With the correct glue, it bonds as well as wood to strengthen the joint. It's softer and more resilient than ebony and therefore, absorbs impact to protect much better than any wood, and, if you bind one guitar in top grade rich dark ebony, and another in ABS and hold them side by side once the finish is on, you would be hard pushed to tell one from the other.

Also, ABS is easy to apply and can be purchased in length to go completely around a guitar in one hit avoiding the need for a joint at the tail. ABS is easy to cut and does so more predictably than ebony so mitre joints are more likely to be crisp, it requires no heat for bending, holds easily in place for gluing, 'and' it's cheap as chips.

This makes a lot of sense. I am planing a scoop style cutaway on this one with ebony featuring in the scoop so I am thinking that It would be best to match it with ebony to try and make it look seamless as possible? I wonder what the guys that do arm rests black use. Possibly they match the bindings with an ebonized veneer?

Thanks again.

Jeremy D

Re: Ebony Bindings

Before you settle on ebony, or veneer, or whatever wood product over ABS plastic, just take little bit of each and coat with a dab of finish, and then see if you can tell them apart without resorting to a magnifying glass. I've used both, even on the same guitar, and black under a finish all looks the same.... shiny black.

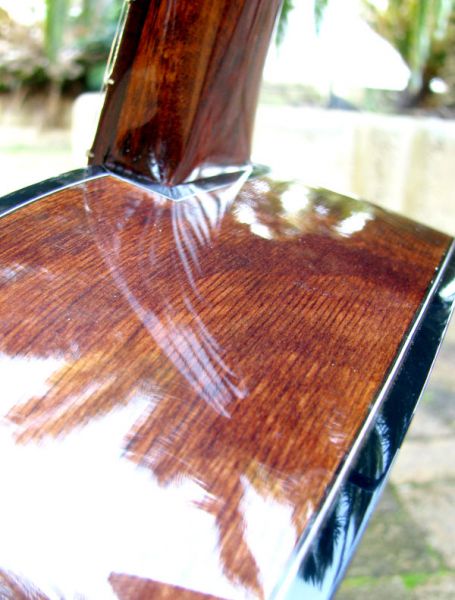

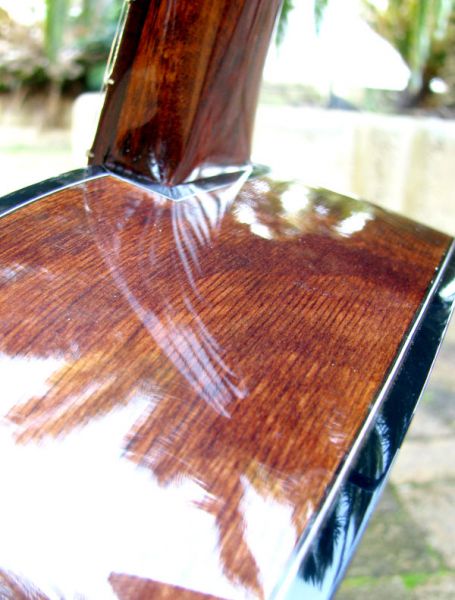

Here's an image showing both ABS and ebony used together. Obviously the neck on this guitar is heelless and I wanted to be able to slide it out to make adjustments etc. This meant the small pieces of binding either side of the neck pocket would need to be removable. The solution was to install them with a metal strip glued to the back of them so they would hold in place when position with the aid of small rare earth magnets inlay ed into the body of the guitar. Once the neck bolts have been removed, the neck can now be withdrawn from the pocket with the two small pieces of binding simply swinging out of the way. This is why you can see small gaps at the miters, a necessary evil under the circumstance.

Aside from the two small pieces, the rest of the guitar is bound with ABS. The only reason I needed to use ebony at all was for those little bits as it allowed the above-mentioned metal shims to be epoxied onto the back of each where as they would not have bonded well had I used ABS.

Cheers

Kim

Here's an image showing both ABS and ebony used together. Obviously the neck on this guitar is heelless and I wanted to be able to slide it out to make adjustments etc. This meant the small pieces of binding either side of the neck pocket would need to be removable. The solution was to install them with a metal strip glued to the back of them so they would hold in place when position with the aid of small rare earth magnets inlay ed into the body of the guitar. Once the neck bolts have been removed, the neck can now be withdrawn from the pocket with the two small pieces of binding simply swinging out of the way. This is why you can see small gaps at the miters, a necessary evil under the circumstance.

Aside from the two small pieces, the rest of the guitar is bound with ABS. The only reason I needed to use ebony at all was for those little bits as it allowed the above-mentioned metal shims to be epoxied onto the back of each where as they would not have bonded well had I used ABS.

Cheers

Kim

Re: Ebony Bindings

Thanks heaps Kim. You may have just convinced me. So what is the best supplier of ABS and do I just use CA to glue them on?Kim wrote:Before you settle on ebony, or veneer, or whatever wood product over ABS plastic, just take little bit of each and coat with a dab of finish, and then see if you can tell them apart without resorting to a magnifying glass. I've used both, even on the same guitar, and black under a finish all looks the same.... shiny black.

Here's an image showing both ABS and ebony used together. Obviously the neck on this guitar is heelless and I wanted to be able to slide it out to make adjustments etc. This meant the small pieces of binding either side of the neck pocket would need to be removable. The solution was to install them with a metal strip glued to the back of them so they would hold in place when position with the aid of small rare earth magnets inlay ed into the body of the guitar. Once the neck bolts have been removed, the neck can now be withdrawn from the pocket with the two small pieces of binding simply swinging out of the way. This is why you can see small gaps at the miters, a necessary evil under the circumstance.

Aside from the two small pieces, the rest of the guitar is bound with ABS. The only reason I needed to use ebony at all was for those little bits as it allowed the above-mentioned metal shims to be epoxied onto the back of each where as they would not have bonded well had I used ABS.

Cheers

Kim

BTW that's a real interesting instrument there Kim. Binding looks great too. Cheers.

Jeremy D

Re: Ebony Bindings

Thanks for the compliment Jeremy,Jeremy D wrote:So what is the best supplier of ABS and do I just use CA to glue them on?

Cheers.

Here's a link to that full rebuild if ur interested viewtopic.php?f=1&t=1903&hilit=matey

You can use a number of glues for ABS bindings including a mix of ABS shavings of the same colour and good old acetone. But whatever you use it is very important to wait 'at least' 24 hrs (better 48) 'before' scraping back to flush. This is because all of the glues that work well with ABS are going to make it swell up to a degree. Therefore, you need to allow time for things to 'gas off' so the bindings shrink back again. If you jump in early, plastic bindings 'will' end up sitting below level and that is sure to be a piss off for anyone. \

After the wait and they've been scarped level, ABS bindings should be treated like any other wood bindings, simply sand with the rest of the instrument, seal (pure blonde wax free shellac works well) and then finish with whatever.

This bloke has a video on mixing acetone and ABS shavings to make glue, http://theaccidentalluthier.blogspot.co ... art-3.html

And here is an old topic on this forum dealing with that and other questions related to Ebony v ABS bindings... viewtopic.php?f=1&t=2314

As for a supplier of ABS? I got my last lot from Gerard Gilet, top bloke but I believe he's moved on to focus upon building and the odds and sod are now run by one of his associates at Guitar Woods.

http://www.guitarwoods.com.au/catalog/index.php

I am not sure that Tim Spittle stock ABS bindings however I would recommend checking him first as he is an ANZLF preferred vendor, and Tim can always be relied upon to deliver only the best.

Cheers

Kim

- Mark McLean

- Blackwood

- Posts: 1175

- Joined: Thu Apr 10, 2008 2:03 pm

- Location: Sydney

Re: Ebony Bindings

Yeah, after using ebony bindings on a recent build I would seriously consider using black plastic next time. Ebony is a real bugger to bend. It just snaps a lot of the time. After you curse and bend 8 pieces to get 4 good ones, and then sand it and put a nice finish on it - it looks like black plastic. Only you will know that it is real wood. But maybe that is important to you?

Gerard Gilet had ebony binding strips, with and without maple purflings, last time that I went in there. You need to phone or visit, since a lot of the wood and accessories that he has for sale are not up on the website.

Mark

Gerard Gilet had ebony binding strips, with and without maple purflings, last time that I went in there. You need to phone or visit, since a lot of the wood and accessories that he has for sale are not up on the website.

Mark

Re: Ebony Bindings

+1 for ABS over ebony, ebony is a bastard to bend, it can get into you top when sanding if your not carfull and is just just generally difficult, as Kim said you would be pressed to pick the difference.

Cheers,

Cheers,

Paul .

-

Crafty Fox

- Blackwood

- Posts: 146

- Joined: Sun Mar 06, 2011 3:09 pm

- Location: Perth, WA

Re: Ebony Bindings

If you really want a black wood binding, you could easily stain something, eg,........... anything! Maple bends easily with heat.

Ken

- Dennis Leahy

- Blackwood

- Posts: 872

- Joined: Wed Oct 10, 2007 12:32 am

- Location: Duluth, MN, US

- Contact:

Re: Ebony Bindings

Just to add to the discussion (or add to "Crafty Fox's" reply) woods with a high tannin content can be "ebonized" with ferrous acetate (vinegar with dissolved iron from steel wool.)

Surface applied, it only goes in maybe 1/128" to at best 1/64" inch, but it can be pushed deeper into the wood using vacuum. Not sure about which native woods would work well in Oz/NZ, but American Walnut works well. To gain a deeper black, the wood can be soaked/vacuum infused in a strong tannic acid solution (some leather tanners use the powdered bark from a tree called Quebracho) as a first step, and then soaked/vacuum infused in the ferrous acetate solution.

There used to be a US company that manufactured faux-ebony (they called it "Ebonex"), and I had a chance to use it in a high-end furniture project as an accent wood (when we could not find uniformly black and crack-free ebony at our suppliers.)

Making my own black wooden bindings is on my "to do" list...I have a vacuum unit, I have quebracho bark powder, and I have made batches of ferrous acetate to test it out (that's how I know how far surface treatment goes in.) "One of these days" I'll build the pressure chamber from PVC to actually do this to some sticks of Walnut - probably about 36" x 2" x 1/4", and slice that into bindings.

Dennis

Surface applied, it only goes in maybe 1/128" to at best 1/64" inch, but it can be pushed deeper into the wood using vacuum. Not sure about which native woods would work well in Oz/NZ, but American Walnut works well. To gain a deeper black, the wood can be soaked/vacuum infused in a strong tannic acid solution (some leather tanners use the powdered bark from a tree called Quebracho) as a first step, and then soaked/vacuum infused in the ferrous acetate solution.

There used to be a US company that manufactured faux-ebony (they called it "Ebonex"), and I had a chance to use it in a high-end furniture project as an accent wood (when we could not find uniformly black and crack-free ebony at our suppliers.)

Making my own black wooden bindings is on my "to do" list...I have a vacuum unit, I have quebracho bark powder, and I have made batches of ferrous acetate to test it out (that's how I know how far surface treatment goes in.) "One of these days" I'll build the pressure chamber from PVC to actually do this to some sticks of Walnut - probably about 36" x 2" x 1/4", and slice that into bindings.

Dennis

Another damn Yank!

Re: Ebony Bindings

Hi Dennis:

I've tried ebonizing and can't make a usable product in the shop. I just can't get the penetration needed to allow for any sanding after the fact. I was mainly working toward fingerboards and bridges using black walnut and cherry.

My set-up uses a PVC chamber that allowes me to cycle both pressure and vacuum. Unfortunately, I'm only able to produce about 120psi of pressure and I think that's where most of the problem lies. The initial parts come out looking great, but any sanding whatsoever exposes the underlying wood color.

I sure wish someone could figure this out for the home shop.

Dean

I've tried ebonizing and can't make a usable product in the shop. I just can't get the penetration needed to allow for any sanding after the fact. I was mainly working toward fingerboards and bridges using black walnut and cherry.

My set-up uses a PVC chamber that allowes me to cycle both pressure and vacuum. Unfortunately, I'm only able to produce about 120psi of pressure and I think that's where most of the problem lies. The initial parts come out looking great, but any sanding whatsoever exposes the underlying wood color.

I sure wish someone could figure this out for the home shop.

Dean

- woodrat

- Blackwood

- Posts: 1154

- Joined: Tue Nov 25, 2008 6:31 am

- Location: Hastings River, NSW.

- Contact:

Re: Ebony Bindings

Hi Denis, why wouldn't you prepare the bindings to size and then infuse them? at ~2mm thick the most the treatment needs to "get in" would be ~1mm...Dennis Leahy wrote:Just to add to the discussion (or add to "Crafty Fox's" reply) woods with a high tannin content can be "ebonized" with ferrous acetate (vinegar with dissolved iron from steel wool.)

Surface applied, it only goes in maybe 1/128" to at best 1/64" inch, but it can be pushed deeper into the wood using vacuum. Not sure about which native woods would work well in Oz/NZ, but American Walnut works well. To gain a deeper black, the wood can be soaked/vacuum infused in a strong tannic acid solution (some leather tanners use the powdered bark from a tree called Quebracho) as a first step, and then soaked/vacuum infused in the ferrous acetate solution.

There used to be a US company that manufactured faux-ebony (they called it "Ebonex"), and I had a chance to use it in a high-end furniture project as an accent wood (when we could not find uniformly black and crack-free ebony at our suppliers.)

Making my own black wooden bindings is on my "to do" list...I have a vacuum unit, I have quebracho bark powder, and I have made batches of ferrous acetate to test it out (that's how I know how far surface treatment goes in.) "One of these days" I'll build the pressure chamber from PVC to actually do this to some sticks of Walnut - probably about 36" x 2" x 1/4", and slice that into bindings.

Dennis

"It's never too late to be what you might have been " - George Eliot

- Dennis Leahy

- Blackwood

- Posts: 872

- Joined: Wed Oct 10, 2007 12:32 am

- Location: Duluth, MN, US

- Contact:

Re: Ebony Bindings

My thought is that the pieces cut all the way to the binding stage would probably look like fettuccine noodles after being soaked multiple times in water-based solutions. I am thinking that a 1/4" thick (flatsawn) "micro-slab" of 2 to 3 inches wide could be held in a drying rack with stickers/spacers and be "tamed" into being flat - and that could be cut into quartersawn binding strips.woodrat wrote:Hi Denis, why wouldn't you prepare the bindings to size and then infuse them? at ~2mm thick the most the treatment needs to "get in" would be ~1mm...Dennis Leahy wrote:... some sticks of Walnut - probably about 36" x 2" x 1/4", and slice that into bindings.

Dennis

Cutting bindings to size first is worth a try, however. Once they have undergone the chemical change (which I don't think would leech-out in water), maybe they could be soaked in hot water to make them pliable, and pressed flat. Or, maybe they would be pliable enough as they come out of the ferrous acetate solution to press them.

:~)

Dennis

Another damn Yank!

Re: Ebony Bindings

"Cultures across the world believe that certain substances have the power to heighten sexual desire or even improve sexual performance in humans. Known as aphrodisiacs, these substances may range from foods to herbs and animal parts. Quebracho is one such herb which has since ancient times been used in the South American continent as an aphrodisiac especially for women."Dennis Leahy wrote: I have quebracho bark powder.....

Martin

- Dennis Leahy

- Blackwood

- Posts: 872

- Joined: Wed Oct 10, 2007 12:32 am

- Location: Duluth, MN, US

- Contact:

Re: Ebony Bindings

It's easy to find the women in the village that drank quebracho tea - their lips, teeth, tongue and throat are stained brown. Then there are the side effects: "quebracho ... can cause some side effects including drooling, headache, outbreaks of sweating, dizziness, stupor, and sleepiness. In large doses, it can cause nausea and vomiting."kiwigeo wrote:"Cultures across the world believe that certain substances have the power to heighten sexual desire or even improve sexual performance in humans. Known as aphrodisiacs, these substances may range from foods to herbs and animal parts. Quebracho is one such herb which has since ancient times been used in the South American continent as an aphrodisiac especially for women."Dennis Leahy wrote: I have quebracho bark powder.....

Not exactly describing a dream date! hahahaaha

Dennis

Another damn Yank!

-

jeff crisp

- Beefwood

- Posts: 23

- Joined: Wed Jul 31, 2013 3:00 pm

Re: Ebony Bindings

I love timber bindings so l would not (necessarily) want to put anybody off using them. But one other perhaps minor consideration is the care needed when fine sanding so as not to spread black dust all over your spruce top or light coloured sides.

- needsmorecowbel

- Blackwood

- Posts: 974

- Joined: Sun Oct 04, 2009 7:48 pm

- Location: Melbourne

Re: Ebony Bindings

How do you prevent the darker dust getting onto the spruce or lighter sides? Shellac?

Stu

Stu

-

pat foster

- Myrtle

- Posts: 79

- Joined: Tue Apr 14, 2009 8:41 am

- Location: Eastern Washington, USA

- Contact:

Re: Ebony Bindings

African blackwood works pretty well for the scoop/bevel, plus it can have faint grain color. Bends easier than ebony.Jeremy D wrote:

This makes a lot of sense. I am planing a scoop style cutaway on this one with ebony featuring in the scoop so I am thinking that It would be best to match it with ebony to try and make it look seamless as possible? I wonder what the guys that do arm rests black use. Possibly they match the bindings with an ebonized veneer?

Thanks again.

Personally, I like ebony bindings if I can get it with some color. I've had some with awful runout, which made it impossible to bend, otherwise it's not too bad.

Pat

Re: Ebony Bindings

Thanks for posting Pat, your L-00 build is actually one of the inspirations for this build. There is also a nice build along on the OLF by Burton Legeyt that shows his process for doing the scoop cutaway. Do you have any tips that might help?pat foster wrote:African blackwood works pretty well for the scoop/bevel, plus it can have faint grain color. Bends easier than ebony.Jeremy D wrote:

This makes a lot of sense. I am planing a scoop style cutaway on this one with ebony featuring in the scoop so I am thinking that It would be best to match it with ebony to try and make it look seamless as possible? I wonder what the guys that do arm rests black use. Possibly they match the bindings with an ebonized veneer?

Thanks again.

Personally, I like ebony bindings if I can get it with some color. I've had some with awful runout, which made it impossible to bend, otherwise it's not too bad.

Pat

Jeremy D

- peter.coombe

- Blackwood

- Posts: 750

- Joined: Fri Oct 15, 2010 2:52 pm

- Location: Bega, NSW

- Contact:

Re: Ebony Bindings

+1 on that. I hate plastic on high end instruments.Personally, I like ebony bindings if I can get it with some color. I've had some with awful runout, which made it impossible to bend, otherwise it's not too bad.

Ebony is not so bad if you go reasonably slow and careful. Guitars are easy, mandolins are more difficult and I have made plenty with Ebony bindings. There are harder woods to bend than Ebony. Just try NSW Ironwood. Nice looking bindings, but a right bastard to bend. Black Ebony dust is also not too difficult to control. You just need to be a bit more careful how you sand the instrument, and sand the top last.

Peter Coombe - mandolin, mandola and guitar maker

http://www.petercoombe.com

http://www.petercoombe.com

-

jeff crisp

- Beefwood

- Posts: 23

- Joined: Wed Jul 31, 2013 3:00 pm

Re: Ebony Bindings

Stu I find closing the pores more than I normally would with finer sanding is a good place to start. Random orbitals are a big help with tops and backs. If hand sanding, fine/finish sanding in one direction (not back and forth) slightly askew of the grain on the sides helps.needsmorecowbel wrote:How do you prevent the darker dust getting onto the spruce or lighter sides? Shellac?

Stu

- needsmorecowbel

- Blackwood

- Posts: 974

- Joined: Sun Oct 04, 2009 7:48 pm

- Location: Melbourne

Re: Ebony Bindings

Thanks Jeff, makes sense now

- charangohabsburg

- Blackwood

- Posts: 1818

- Joined: Sat Oct 16, 2010 1:25 am

- Location: Switzerland

Re: Ebony Bindings

And many customers (not all though) will associate plastic binging with cheap or cheaply built instruments, I have the impression that stained wood has a much better acceptance.peter.coombe wrote:+1 on that. I hate plastic on high end instruments.Personally, I like ebony bindings if I can get it with some color. I've had some with awful runout, which made it impossible to bend, otherwise it's not too bad.

I have never bent or tried to bend ebony, but I have bent bindings with horrible runout (pear and maple) into really tight curves (10 mm radius), which was not at all a problem after having it glued up out of two thinner strips. I imagine that this should work with ebony too.

Markus

To be stupid is like to be dead. Oneself will not be aware of it.

It's only the others who suffer.

To be stupid is like to be dead. Oneself will not be aware of it.

It's only the others who suffer.

Who is online

Users browsing this forum: No registered users and 79 guests