Nice work everyone. I'm particularly digging a bit more archtop action.

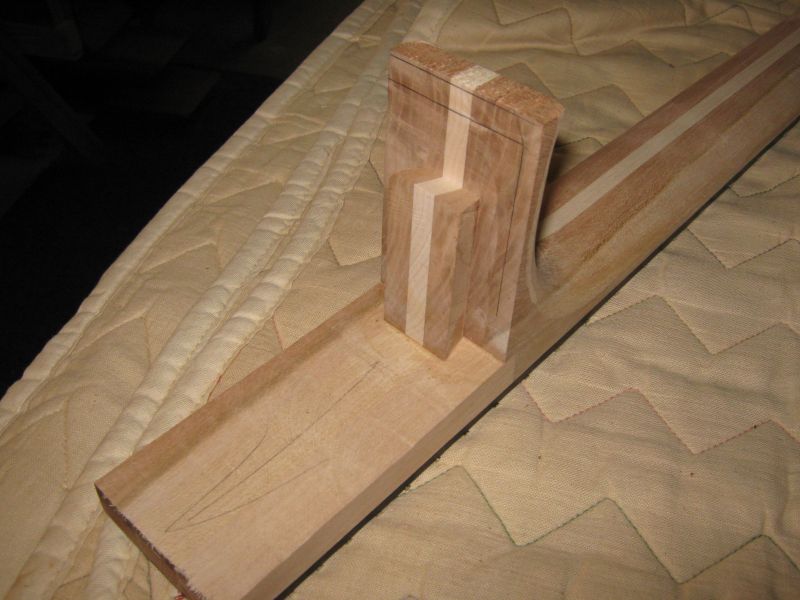

Made this little hand plane for archtop shaping. So easy to make and customise I can't see myself buying shaping planes again. Just some more good blades.

I used wood from my 'too good to throw away" box. Set the bed angle on my drop saw. Glued it up with the mouth shut and carefully opened it up when I sanded the bottom shape. The metal rod is placed so the blade is a friction fit. I had to file the underside slightly to get the blade in. If it gets loose I can bend the rod in slightly.

Its set up as a hogging plane and works exceptionally fast even on hard maple. Best thing about wood bodies is they don't get hot and burn your fingers like the Sloan style planes when you go hard at it.

Not really on my bench but near it ...

Finally got my dust extractor all hooked up and the main 150mm line in. Waiting for fittings to move in and finish hooking up the rest of my tools. Working on Bill Pentz's info where he strongly advises against reducing duct size at the machine because it significantly kills airflow. So I am running 150mm flex to each machine and enlarging the flanges.

Cheers

Dom