Both the top (Adirondack Spruce) and the back and sides (Venezuelan Cocobolo) came from Bob Cefalu at RCTonewoods.

You can see that the Adi top has lots of late growth in it (the dark stripes) which makes it extremely stiff. It also makes it a lot denser and heavier.

There is up to 120 grams difference between some of the Adi tops I have.

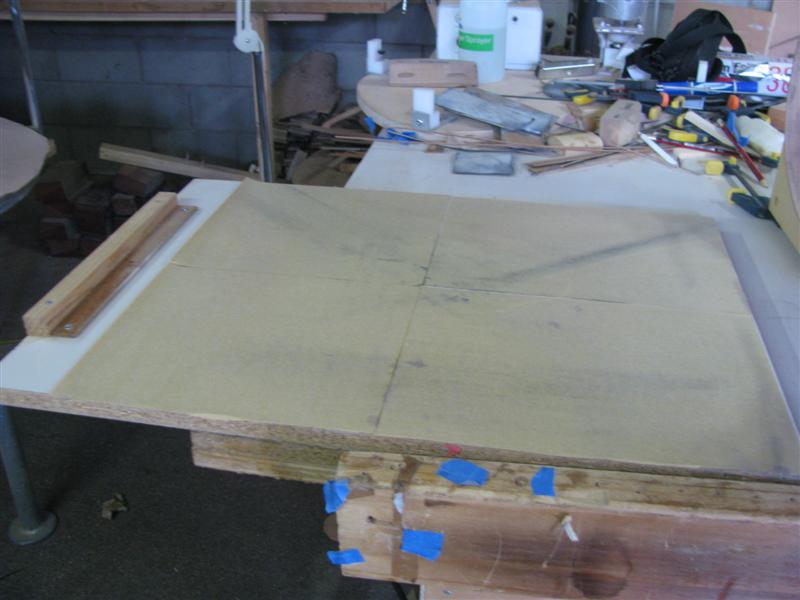

The top was joined using a Jet jointer. I then put some 3M Stickit sandpaper on to the bed of the jointer and make a couple of passes of the top on the sandpaper (which generally ensures a tight joint)

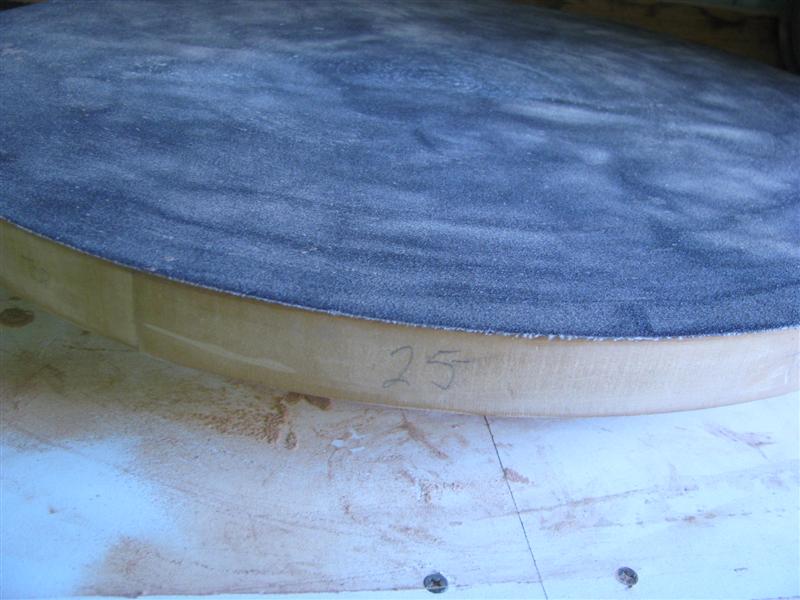

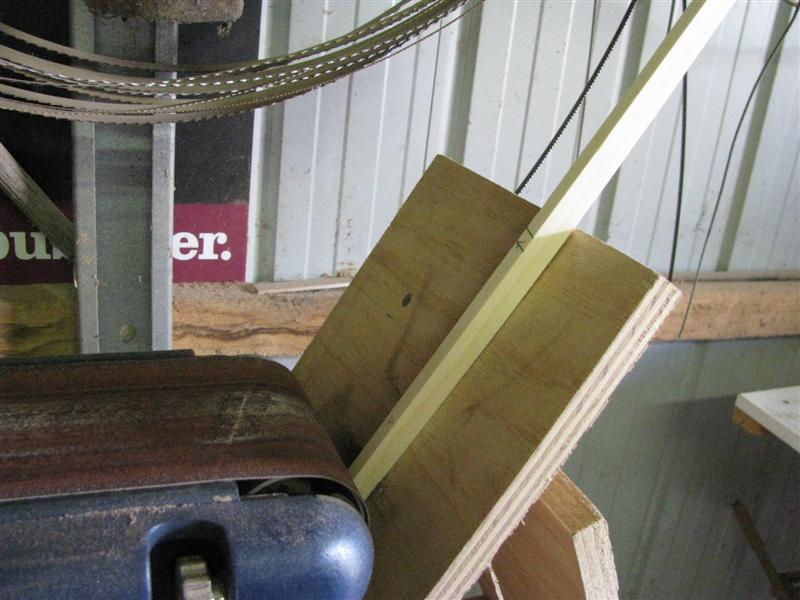

The Cocobolo is extremely oily and will clog up the paper on your drum sander in no time at all.

I keep a roll of 40 grit paper just for jobs like this. It will get your wood down to thickness reasonably quickly without clogging up like 80 grit does.

In this case I was thicknessing the sides which I wanted to end up at .080". I took them down to .095" with the 40 grit and then swapped to the 80 grit to end up with the dimensions that I wanted (which ended up around .081"-.082")

I then sanded with the random orbital with 120 grit before bending.

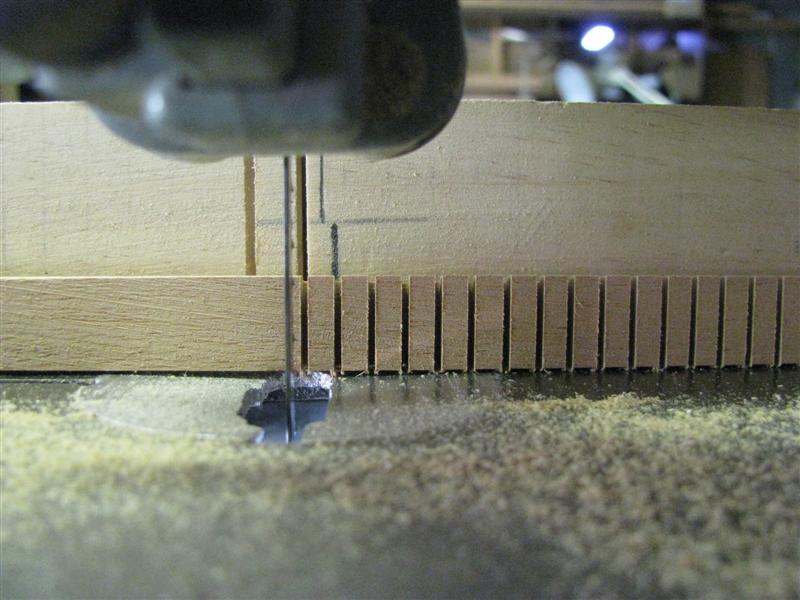

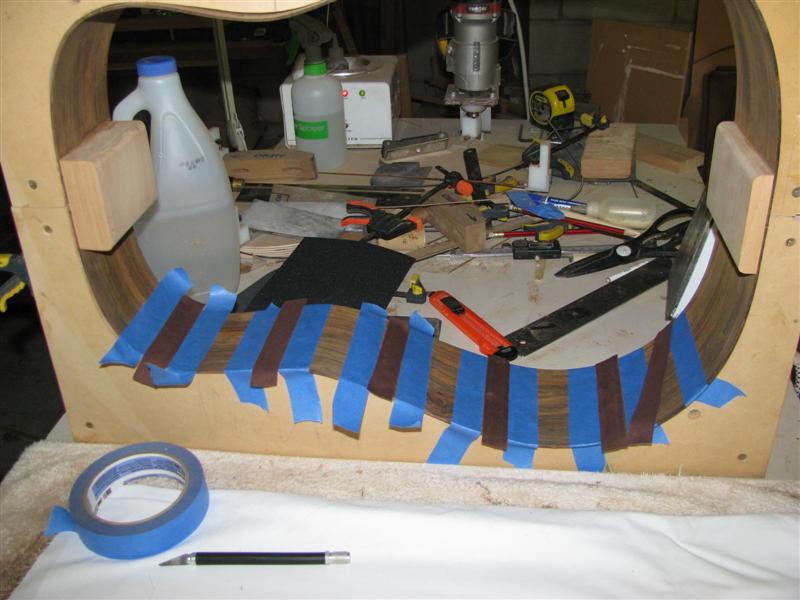

I used my now standard procedure for side bending, which is to sandwich the sides firstly in kraft paper, the spritz lightly with water and then wrap in aluminium foil.

Then heat the sides in the Fox bender, starting the lower bout bend when the temperature hits 100c. Then do the upper bout and finally screw it all down. Watching the thermometer allow it to reach 150c and them turn it off and allow to cool.

This Coco bent easily with very little springback.

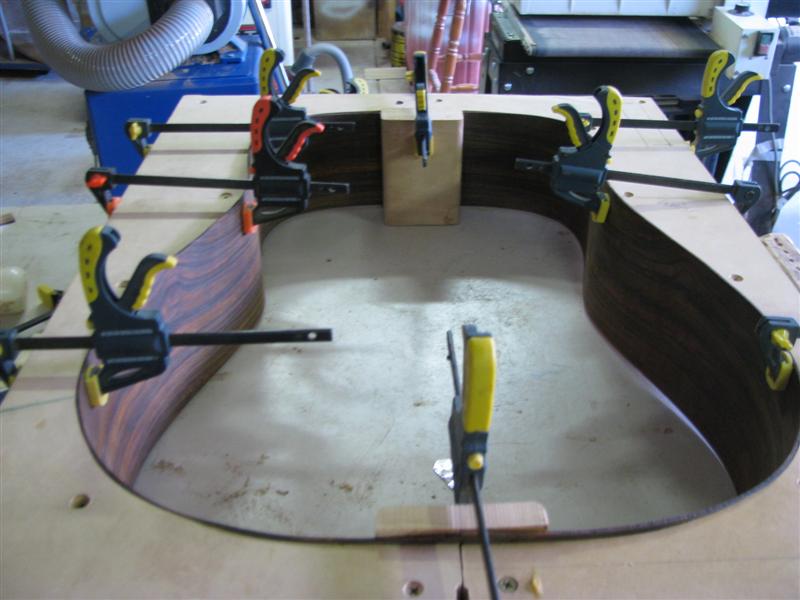

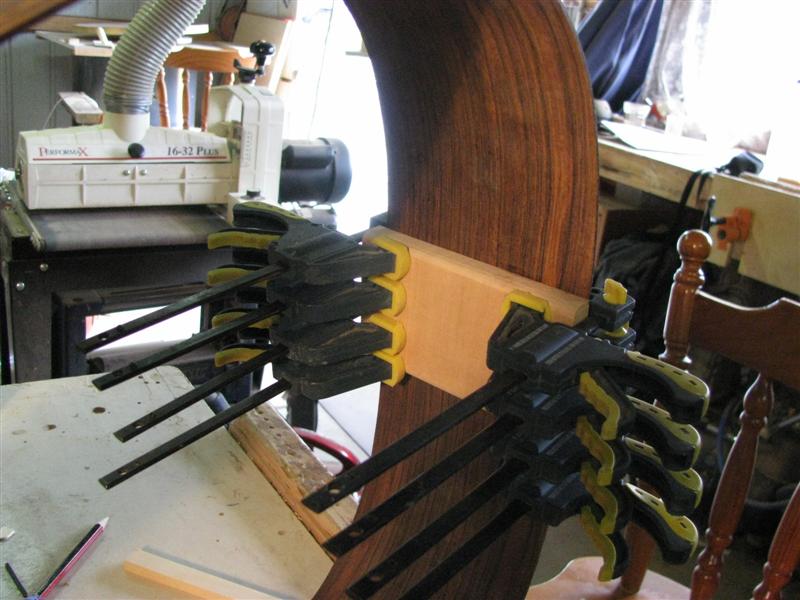

The next step is glueing in the neck and tail blocks. We used to do this in the mold but it proved problematic so we now do it before insering the sides into the mold.

So far I've had no reaction to the Cocobolo.

Thanks fer lookin'. To be continued