Of course you can also weld a blade. Once on another forum someone even told me that if a broken blade was not welded it would not hold together. I can tell you the opposite because I have done it over and over, and every time when the the blade did break again it did at another spot. I reckon he never had repaired a blade, neither brazing nor welding. Just another nerd.

The blade will break again earlier if it was poorly aligned and, even without bumping, will move back and forth when running. So it is essential to get it really well aligned. My first jig for aligning was way too short and yielded poor (but for resawing still usable) results, but those repairs usually did not last long, but it took a long time for aligning in a halfway decent manner when it came to the next repair.

First, the broken ends have to get squared and bevelled for the scarf joint. To get the same bevel on both ends I clamp them together and grind the bevel on the grinding wheel (using leather gloves, it's kind of a scary action, don't let the grinding wheel catch the blade...)

Then align the blade on the jig, lay some tiny pieces of brazing material on top of the joining line and apply some heat. I use a cheap CampingGaz-like aerosol blowlamp - cheaper than these here. You really don't need a lot of power to get this ridiculous amount of steel to cherry red.

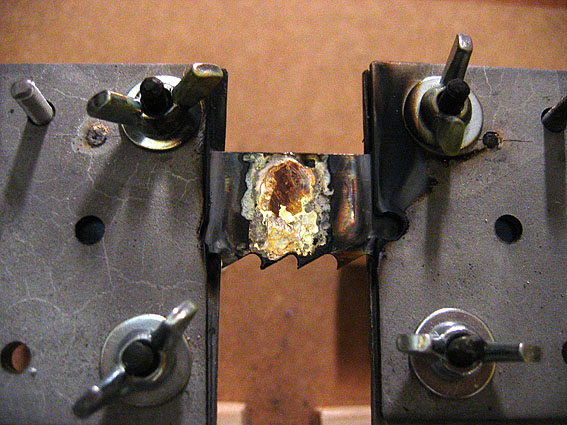

Then it will look a bit like this:

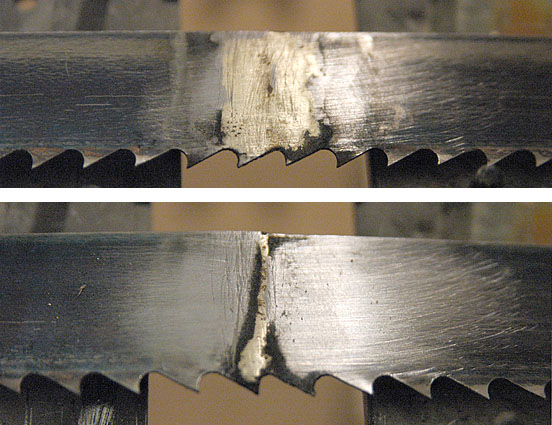

File away the excess material, and it will look a bit like this but hopefully better aligned (it's a photo from my beginnings) :

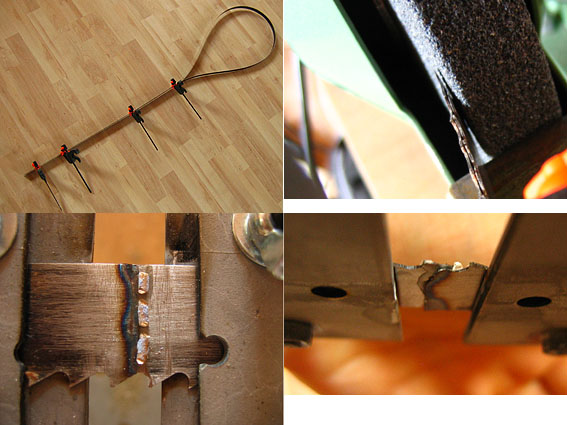

My first aligning jig was about 4cm between the indexing/aligning pins at each side, and it was a royal pain to get that blade right, it cost me every time about 20 minutes! Then I decided to spend some money on a 80 cm long rectangular cross section steel tube. The indexing/aligning pins for each blade end are now 35cm apart, and it takes less than 3 minutes to shove the blade in, tighten slightly the 8 wing nuts, lay out some brazing material on the blade and bring it uf to the right temperature. This is how the new aligning jig looks like:

That's an intact blade I put in here as I shot the photo right now and had no broken blades around.

Here you can see the the aligning pins:

I hope this will save you some money and a lot of time. Going through the whole procedure is almost faster than firing up the computer to order some more blades, and after less than 10 minutes you go ahead with whatever you were cutting into pieces.