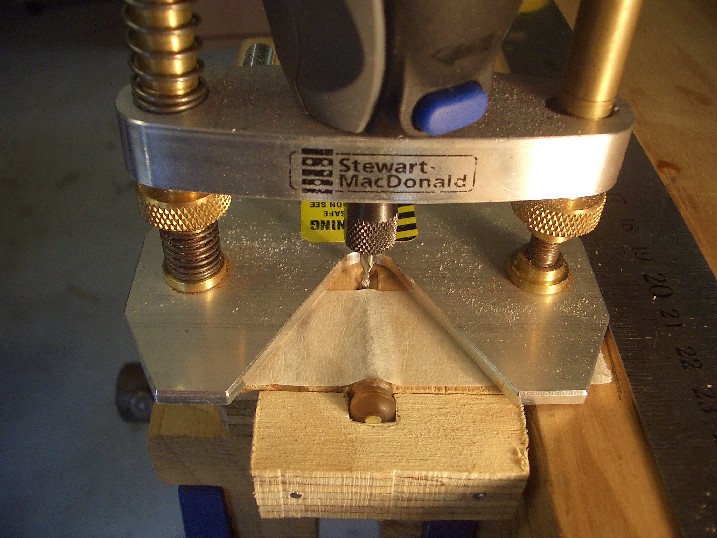

Cut a slot in a piece of scrap timber with a 6mm bit, and then ream it into a tapered shape using a bridge pin reamer. I nailed and glued a T-piece on the back of this so that it can be put in a vise.

The pin holder is flush with the benchtop and the ruler is clamped there to act as a straight edge to guide my Dremmel base. The piece over the head of the pin holds it in the slot. As you can see, it is all pretty rough and I made it in 10 minutes. No inlay work on this jig, Craig.

The masking tape holds it down, and there is a 1/16" bit in the Dremmel set it to the desired depth. It is good to have the slot a bit longer than the pin so that you can set the depth and start the bit in that space at the end. Adjust the straight edge so that it is parallel to the long axis of the pin and at the correct distance.

Start the motor and cut your slot. I took one pass to the head of the pin and then ran back down again. There is quite a lot of dust so have the vacuum handy (you don't want to inhale that organic stuff).

Here it is immediately after cutting. Clean it up with some 600 grit and it will look great and hold that string forever.