Multiple use dial indicator

Posted: Wed May 27, 2009 1:09 pm

Getting your moneys worth from a dial gauge

Some of the jigs shown here have been posted by other members in the past but I thought I would show mine as they all use the same dial gauge. Luthiers are a pretty inventive lot so you all my have the same jigs or tools already, I hope you did not buy 4 dial gauges.

The parts used are all reclaimed, even the dial gauge that is used I took from my old thickness caliper, which I have since resurrected, see photo.

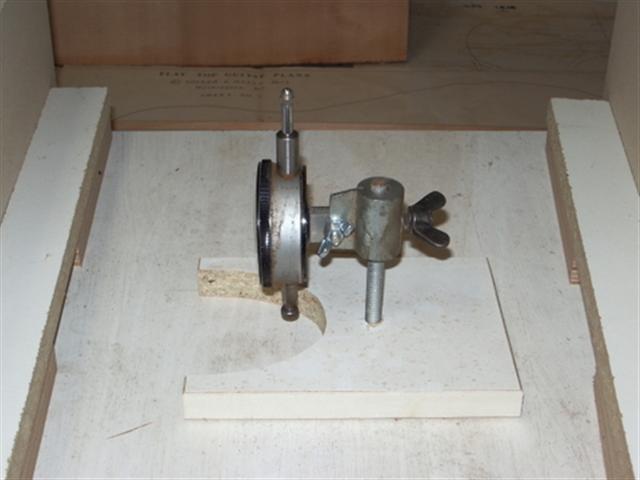

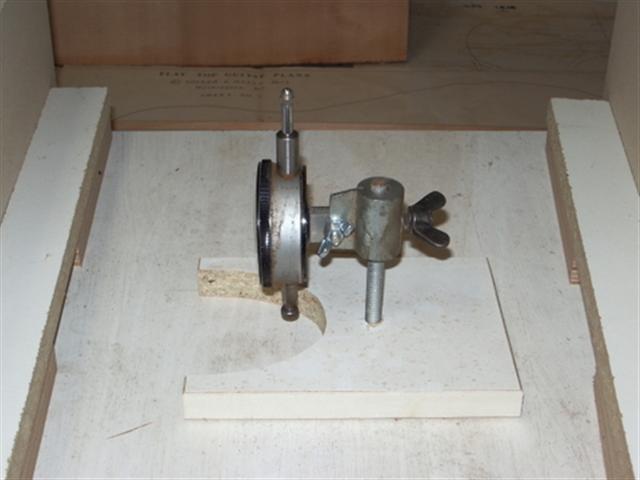

What I use is a fitting from a Makita drill that bolted onto the side of the tool. A rod could be inserted and clamped into the hole and was used as a depth gauge. The rods I used I cut up from parts of old music stands that I had saved. A long bolt cut to the appropriate size could also be used. Then you just make devises to hold the rod the rod and slide the gauge on and tighten the wingnut

Shown in the photos are:

The dial gauge with the fitting and rod attached

In the drill press as thickness caliper

On stand for plate flex testing jig:caliper

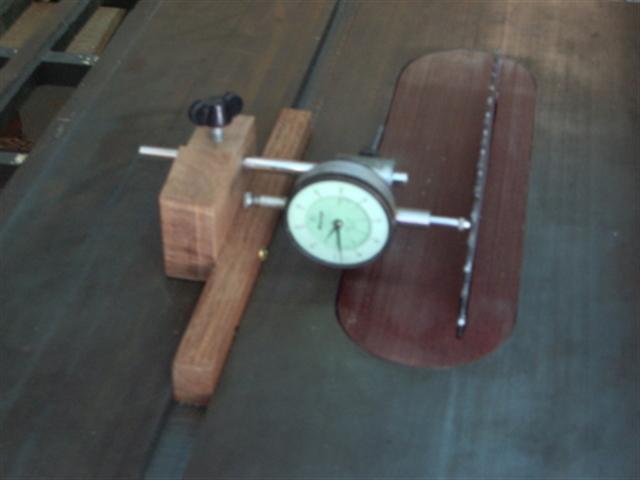

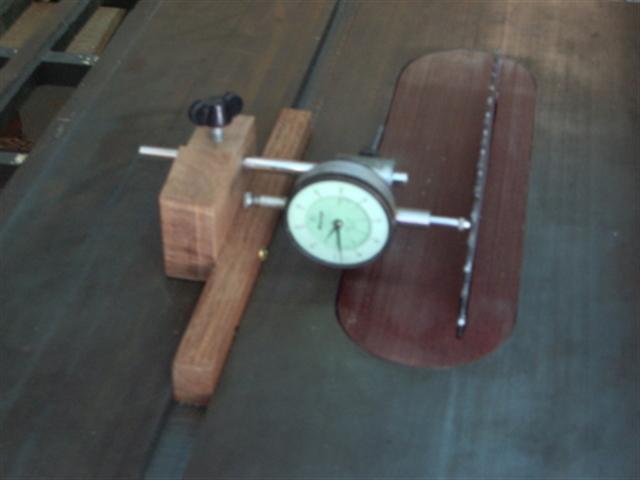

Fitted to jig for adjusting the alignment of saw blade or fence

Whilst in Adelaide I bought a new gauge and fitted it to my old caliper that I made back in the late 1970’s. It was very hard to cut, I found out the guy who gave me the steel got it from a tank, it was it was amour plating

Thanks for looking.

Some of the jigs shown here have been posted by other members in the past but I thought I would show mine as they all use the same dial gauge. Luthiers are a pretty inventive lot so you all my have the same jigs or tools already, I hope you did not buy 4 dial gauges.

The parts used are all reclaimed, even the dial gauge that is used I took from my old thickness caliper, which I have since resurrected, see photo.

What I use is a fitting from a Makita drill that bolted onto the side of the tool. A rod could be inserted and clamped into the hole and was used as a depth gauge. The rods I used I cut up from parts of old music stands that I had saved. A long bolt cut to the appropriate size could also be used. Then you just make devises to hold the rod the rod and slide the gauge on and tighten the wingnut

Shown in the photos are:

The dial gauge with the fitting and rod attached

In the drill press as thickness caliper

On stand for plate flex testing jig:caliper

Fitted to jig for adjusting the alignment of saw blade or fence

Whilst in Adelaide I bought a new gauge and fitted it to my old caliper that I made back in the late 1970’s. It was very hard to cut, I found out the guy who gave me the steel got it from a tank, it was it was amour plating

Thanks for looking.