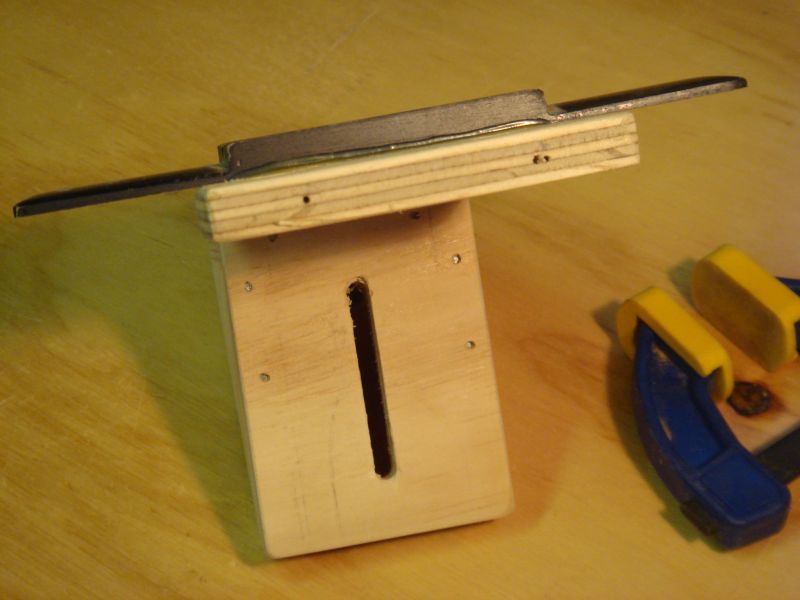

When I was gluing on the bridges I wanted to make sure I had the best compromise for intonation. I had the dimensions from the kits but thought it would be a mission to fix if they weren't right, (saddle slots were already cut) so I set up the bridges and saddles in the advised position without any glue, then screwed this jig into a small hole I had made as a pilot for the end pin, to act as a temporary tailpiece.

The slot in the back part allows for different depths of body. I used a wood screw with a washer through the slot and into the end pin hole.

I then put a new top and bottom E string through the two small holes in the end of the jig (set low to get the best possible angle over the saddle) and tied them off at the old scrap bridge, then tuned them to full pitch and checked the intonation with a tuner. I adjusted the bridge position until I had the best compromise of intonation, while keeping the bridge square, then marked the bridge position, dissassembled the jig and glued the bridge in place.

The jig will work on any guitar and can be used for steel or nylon strings. I need to put some felt pads on it so it won't scratch the finish.

How does everyone else do this, or do you rely on measurements and then cut the saddle slot afterwards?

Cheers

Richard