youtu.be/

If you didn't hear the difference you most likely will do when using headphones.

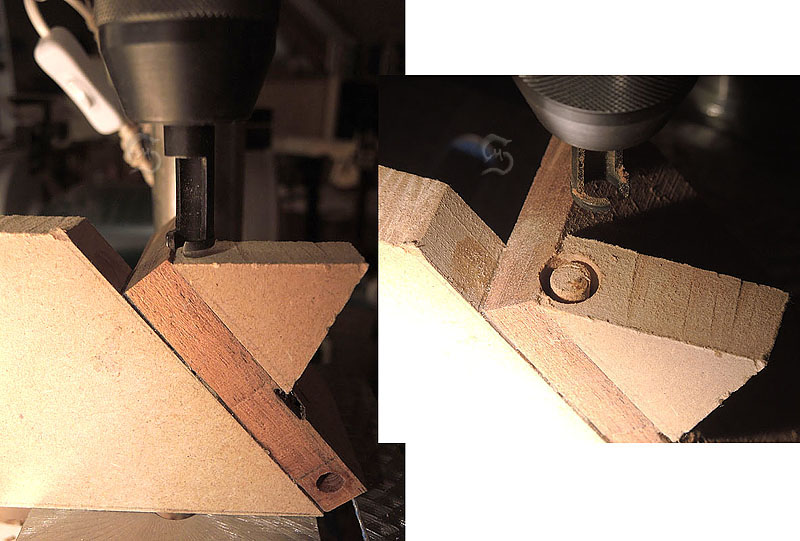

I have to say that the neck at the nut is rather thin for a classical guitar (19 mm opposed to more common 21 mm). Modifying the neck thickness, or even testing the difference neck thickness was making here was absolutely out of consideration, so I proceeded to add some weight to, or should I say into the headstock. A brace and bit is a wonderful tool when it comes to drill a hole in exactly the direction you want, when mounting the work piece beneath a drillpress bit would be a bit too time consuming:

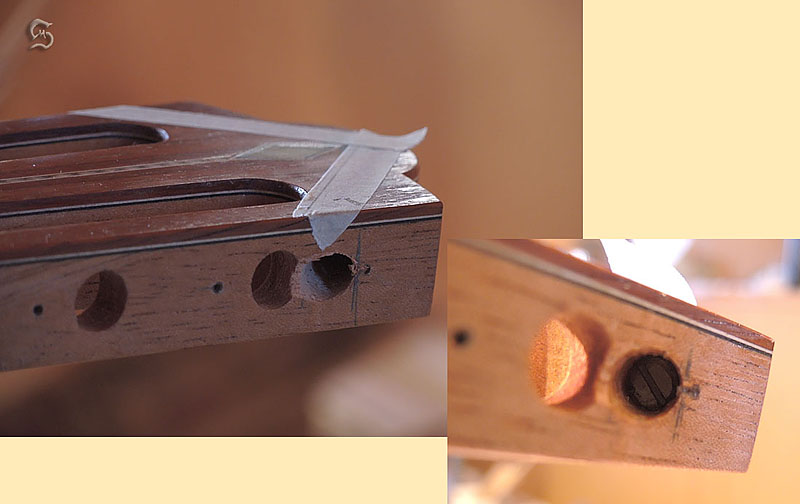

Then I buried two pieces of 35 mm long M8 threaded rod in the two holes, which made an additional weight of 20 grams. I used epoxy to glue them tight, but oiled the threads so that I could get them out again in case the result would not be satisfying:

Next I cut some plugs to give the upper machine plate screws a grip. Getting the plug's grain orientation "correct" is not necessary as the plug will be completely hidden by the machine plate, but it was a good exercise:

Plug is glued in and gets trimmed level:

It worked just fine, problem solved, and it was much cheaper than buying heavier tuning machines (Sloane 300 USD, Alessi over 1k I believe, and so on) .