Last December I had to repair a nasty crack in a charango top that already had been repaired previously by a German guitar maker. He had done a very neat job, but one cleat for a crack that runs from the bottom of the top all the way up to the lower harmonic bar is not enough, not even on a small instrument like this (total string tension of a charango is about the same as the one of a classical guitar). Juan Achá, the maker of this little treasure is one of the most renowned charango makers of Bolivia, and all the tops of his charangos I have measured so far (maybe ten or so) are somewhere between 0.8 and 1.4 mm thin. I won't go into the details of the repair, but the following picture of my completed repair (the two transparent cleats) should illustrate why I wanted to use the lightest and strongest spruce cleats ever found on planet earth: The dark cleats (mahogany I guess) are the ones used by the previous repairer and are about two or three times thicker than the ones I was using.

The crack holds up well and the owner says its sound and playability would be just the same as before.

I believe that not runout-free cleats of the thickness I used would not hold up. Not if that close to the bridge.

I had split completely runout-free cleats out of a discarded (free) spruce top with horrible runout. The cleats are about 25mm long and 0.4 mm thin. The bigger one brought 0.05 grams to the scale (one half of 1/10 gram), which I thought was acceptable.

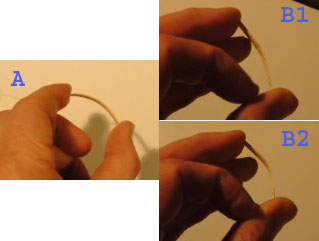

A few days ago I got curious about the difference of behavior between the same spruce of a halfway comparable thickness (this time 0.95 mm), with and without runout. I cut and planed two longish cleats from the same horrible top (runout ratio 1:15 which equals about 3.8°), one just as the top is, with runout (B) ...

...and one from a carefully split piece of that top, ending up with virtually zero runout (A).

Then I proceeded to destroy them

And here the comparison just before they let go:

Between B1 and B2 some wood fibers started to crack audibly, B2 is the last frame before the sample cracked completely and flew across the bench.

Now you may imagine what kind of wood Vicente Arias was using when he built this guitar. Just saying.

If interested, here you can download an article about this Vicente Arias guitar and its history (nothing about runout in spruce tops).

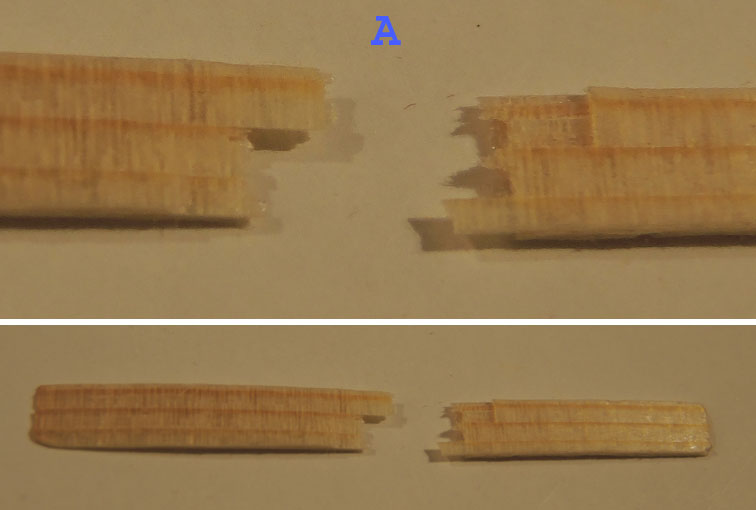

Back to runout: some close-ups of the broken samples and fibers, again (A) = no runout, (B) = runout ration 1:15 (click to enlarge).