Nick, it's not perfect by any means, as you'll see. I've already posted this on TLC but I suppose it won't hurt to show it here.

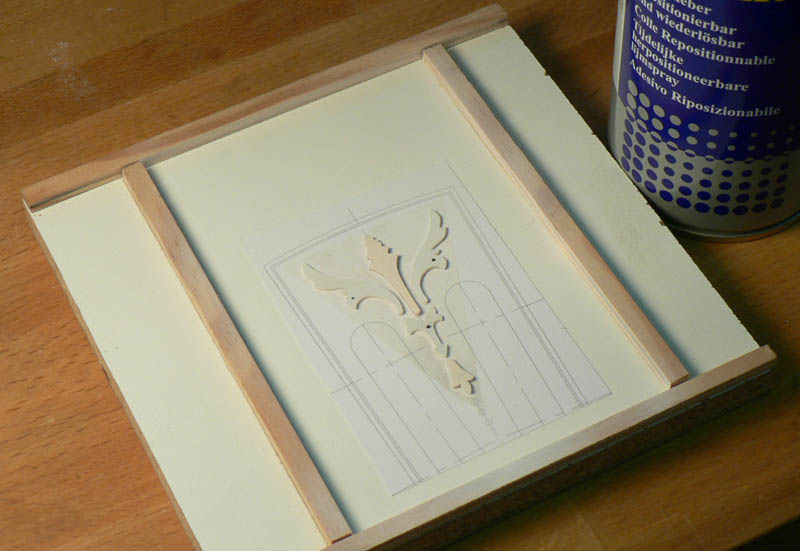

Once I'd cut out the shell pieces I used 3M re-positionable spray adhesive to position them

face down (don't forget) on a board. I then gave them a coat of 'mould-relase' spray. This, in fact, is a Teflon spray I already had for treating saw or jointer tables, etc. Keith uses olive oil which probably works just as well but is a bit more messy.

- TUC 106.JPG (69.99 KiB) Viewed 29967 times

I then warmed up some 'friendly plastic' in hot water. Mine is in fact called Utileplast (a French equivalent) but you can get the real thing from LMI if you don't have it in Oz. I kneaded this well around the shell. Note the 2 spacers stuck to the board.

- TUC 108.JPG (60.99 KiB) Viewed 29967 times

Then, while the plastic was still soft, I put another board on top and squeezed the whole lot up in the vice, and left it to cool down.

- TUC 109.JPG (91.73 KiB) Viewed 29967 times

This gave me my mould with a nice even thickness and it lifted off the shell quite easily.

- TUC 111.JPG (56.96 KiB) Viewed 29967 times

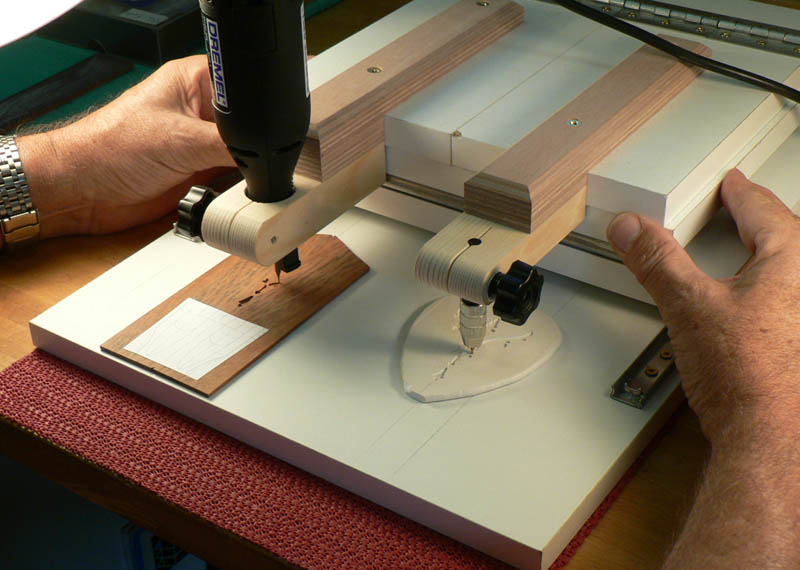

This is the only photo I have of the 'machine' but I'll tell you a few things about it that need to be modified before I use it again. First of all I simplified it a bit by making the Dremel attachment and the stylus fixed. That was a mistake as I had to very carefully align my headplate veneer and the mould to get the inlay in the right position. So either the Dremel or the stylus (or both) needs to be adjustable. Second, as you can see, I used lightweight drawer runners and heavier ones would probably have made it a bit less flexible. To attach the Dremel I bought the accessory for cutting holes in dry walling and used the threaded part. If you think of making one just watch Chris Paulick's video a few times and you'll get the hang of what you need to do. Take note of what he says about 'racking' the hinges to take out the play; I wouldn't have thought of that.

- TUC 112.JPG (86.42 KiB) Viewed 29967 times