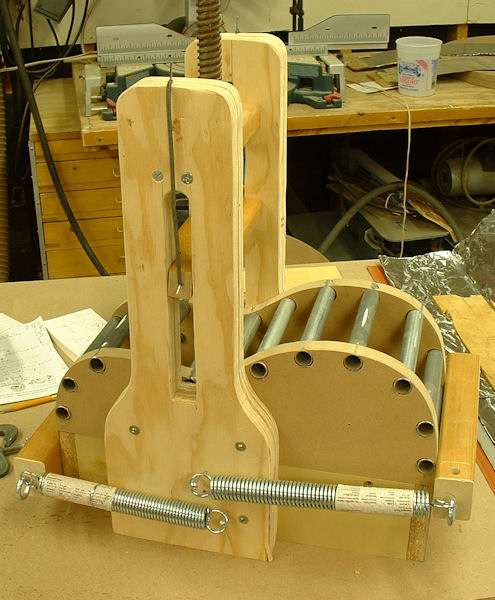

Hi Folks, I did so well with my rosettes I thought I was on a roll and decided to take on side bending. I began using a lightbulb bending form made with an open top and 3/4" pipes. The scrap hardwood I used was easy to bend and I got good results except for some flats on the outsides of the lower and upper bouts. I borrowed a heating blanket from a friend and made a solid form. On the new form I also took a graduated 3/8" off the surface of the end of each bout and took a graduated 1/8" off the waist to help with springback. The form looks good to me.

I then bent saveral pieces of the scrap hardwood (I would give the species, but I don't know the name. It looks like rubber wood with red streaks going through it, has bad splintering, and is blond like rubber wood.) The bending of the scrap went very well.

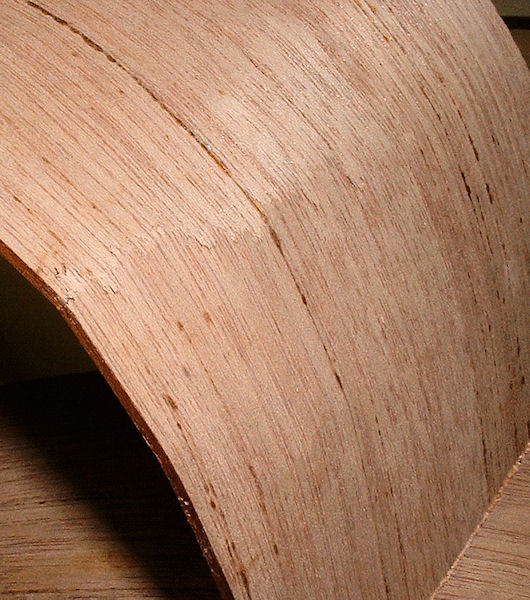

I then bent some of my mahogany. There were flats on the outside of the bouts, plus the waist was cracked. The mahogany is of an uncertain species. It comes from the book shelves my wife grew up with in her childhood home. There were two shelves that were nicely quartered, so I resawed one into sides and a back. They were sanded to between .085" and .090". They looked very nice, a bit boring as mahogany is, but nice.

I tweaked the form a bit and it looked plausable to me that it would bend some nice sides. I put in another scrap piece and got good results. Bent another mahogany and it was just as bad as the first.

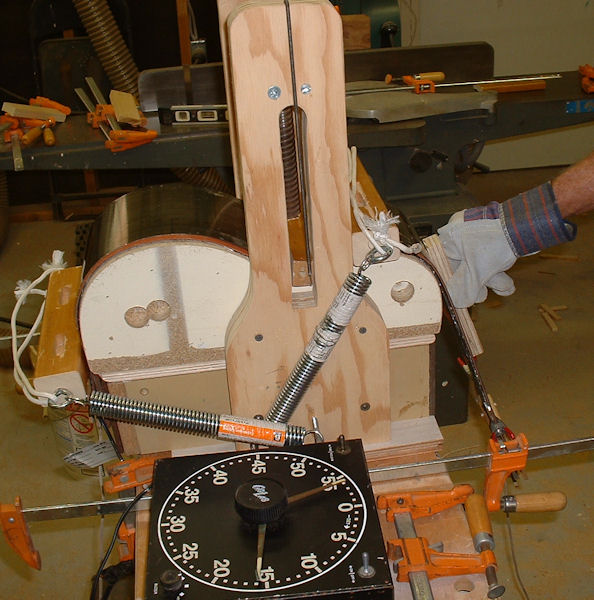

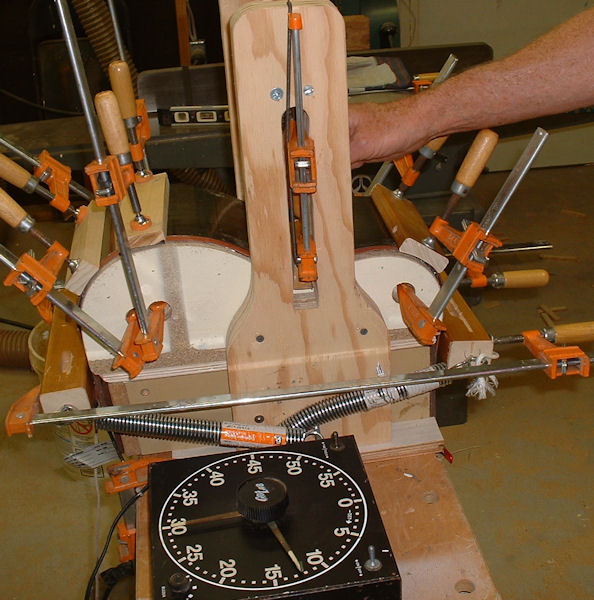

My ritual for bending is to spritz the wood with distilled water, wrap in foil, make the bending sandwich, then place carefully in the bender. Then I heat the sandwich for 3 minutes, lower the waist press slowly and get it to about 1/8"to 1/4" from the mold at the waist. (EDIT - Actually the space is 1/8", not 1/4") I then do the lower bout and bend it by hand until I feel it is flexible, then move the spring loaded caul over the mold to cinch up the sandwich. I bend the other bout next, add the spring caul, and then screw the sandwich down all the way at the waist. I then carefully add some clamps with cauls that are radiused to the area they are to be clamped. I am not, I think, adding too much pressure to the clamps. I add clamps with cauls because the sandwich wasn't snugging up perfectly to the bouts, and I thought the clamps/cauls would help. It appears clamping nor not clamping has no effect on the flats and cracks in the wood.

I am wondering if any of you builders can spot my mistakes. Could it be the mahogany? I am simultaneously building another guitar with pao Ferro sides and have no extra of that wood for sides. You know I am reluctant to go to another wood to bend when I have not perfected the bending on mahogany. Could it be the form? Is my procedure bad? The photos below will show you where I am at, and how I got there. I am temporarily over my head. Help anyone? Thanks, Cactus

This is the form I am no longer using.

Below is my bending procedure

Below are the ##!*+XZ#! cracks and flats I mentioned. Hope you can make them out.