I am attempting two guitars. One is from plans for a Martin size 5 Terz. It will have a spruce soundboard and Pao Ferro back and sides. This guitar will be true to the plans mostly, except both guitars will have 14 frets to the neck instead of 12, and have a slightly longer scale length.

The other guitar will have the same body size and neck as the Terz, but will have very different bracing, a double laminated lightly braced soundboard, and be made with an Alligator Juniper soundboard and mahogany back and sides. The Alligator, an Arizona native, is from a tree I cut ten years ago. It is similar to cedar. The mahogany is from book shelves my wife grew up with in her home in Houston. Three of the shelves were quartered very nicely. I am basing this design on the Outdoor guitar made by a Swiss outfit at www.brunner-guitars.com. Brunner's outdoor guitar is a removeable neck travel guitar. I probably won't make my neck detachable,as airlines now allow me to bring a parlour size onboard as a carry on. I am making my plan from what I can see on their website of how they build their guitars.

DISCLAIMER: The guitar build may take some time to complete, so bear with me. Also, I usually spend half the year away and have no shop to play in, so the build will take at least twice as long as usual for a newby such as myself. Also, I don't know if these two guitars are my FIRST guitars, or my ONLY guitars. I am cutting some corners the professionals would not, such as my funky mold. IF I build a dread in the future I promise I will make a pretty mold for it.

The beginning stages of the build were not documented. A guitar friend, Bob Steidl, resawed the material for me. I, probably unnecessarily, stickered it for the six months I was out of the country. Also, the building of my Fox bender, bending pipes, and guitar mold were not documented.

I have tried to get good pics and have tried to judge how big they should be. If I am taking too much storage space and if my photos should be smaller, please tell me. Any advice or help in taking better photos is welcome.

Most photos will speak for themselves. I will try to anticipate any unanswered questions in the photo and give some explination where necessary.

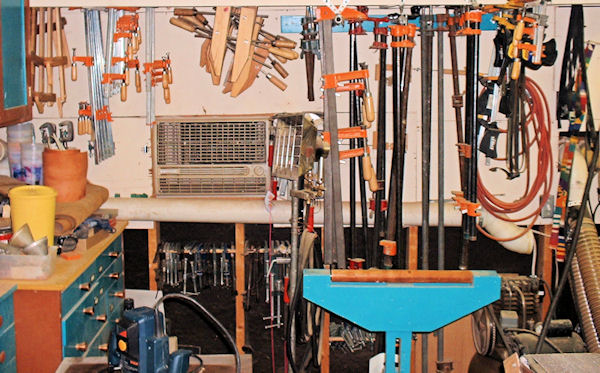

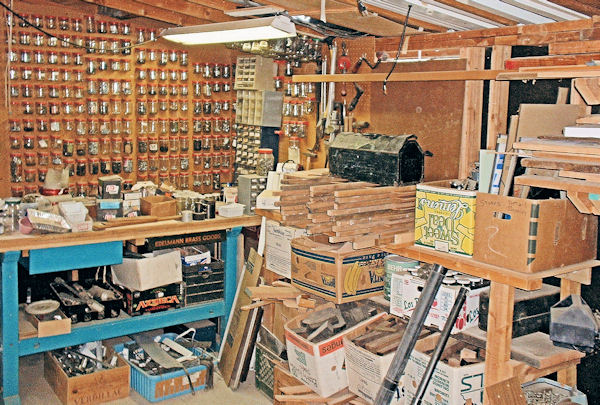

In order to give the complete story of this build I am starting with pics of my shop. Some of you have seem some of these shots before in another post, so just skip ahead if you like.

This is the bat cave where wood and bits and pieces are kept. It is the third bay of the three car garage that is now my shop.

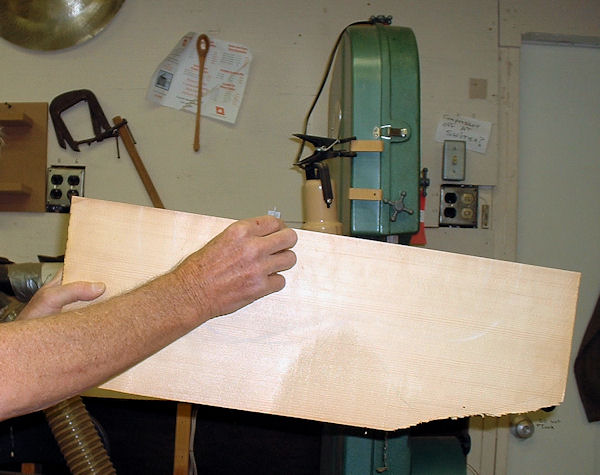

I put a machinist square to it to see how my jointer is doing.

A little warm water at the right time makes it easier later.

KERFING LININGS

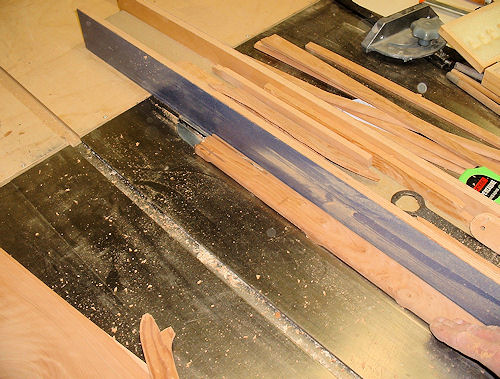

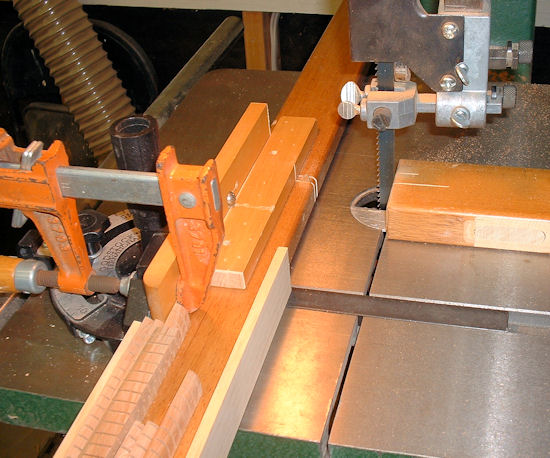

For safety I routed my quarter round on the board, then ripped the lining to thickness.

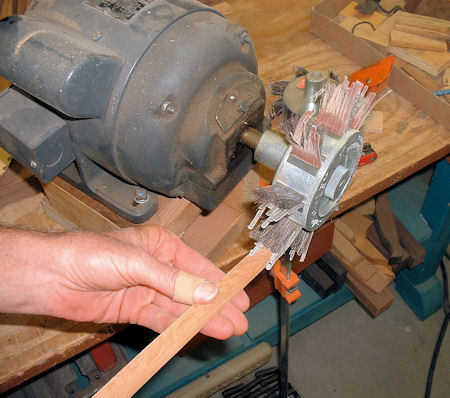

Flap sand the lining

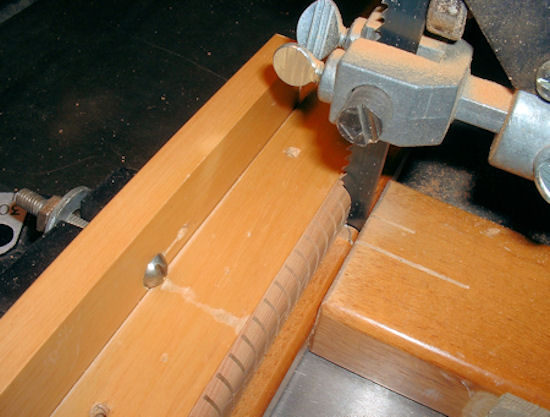

I used a bit of broken off saber saw blade to give me my spacing.

These Alligator Juniper kerfed linings should give me the best smelling guitar body in Arizona.

All for now. I am pretty thick skinned, so please holler if you know something I should know. Always open to advice. Cheers, Cactus