Pic 1. Top left. Thining the part of the side that will be the cutaway to about 1.2mm. Top right. A look at how the headblock joins the sides. Bot left. Screwing a caul into the head block to get the right angle to clamp the odd shape. Bot right Gluing the cutaway to the head block with a cork lined caul to take up the odd shape.

My cauls are usually wraped in plastic as useing epoxy is messy.

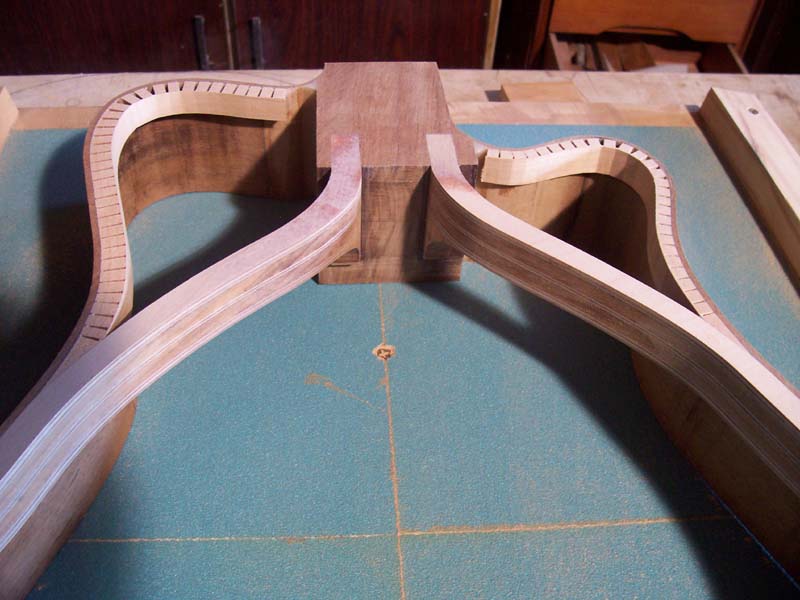

Pic 2 Not sure what to call these, maybe the Head block beams. They are there for a few reasons, to isolate the sounboard and provide a stable solid rim like that on a banjo or resonator guitar and also to stop the neck to body relationship from folding up as it is so common up here in the extended high humidity that I feel it is important to address. They are laminations of 2mm birch aircraft ply and Narra.

Pic 3. Top left The beam being clamped wrapped in glad wrap, epoxy again. Top right Beam fresh out of the clamps. The caul is complicated with dowel because the epoxy is so slippery Bot left The mortise in the head block to take the beams. Bot right Gluing the beams in place.

Pic 4. The beams in place and maple linnings added.

Pic 5. A comparrison against a Fender Telecastor.

All the glue so far is epoxy to beat the heat and high humidity even though its a pain, one positive is its long open time though.

Jim