What's On Your Bench?

You've got a nice pair there, Allen...  I am talking about the ukes...

I am talking about the ukes...

Great craftsman pic Arnt.

Well I have been busy and let me tell you it's been slow going here but I am having fun.

Here is my completed back ready to have the plastic, temporary shield taped over my label to protect it during finishing.

This guitar will be braced a little heaver than I usually do so it can handle mediums and perhaps be a gasser.

I spent an entire day sharpening my edge tool world... In the last year I had made a list of things that I needed to improve on and sharpening chisels and plane irons was one of them. With a few additions to my shop and some ideas from some woodworking friends I think that I have this sharpening thing down now. Anyway all of my edge tools can pop hairs off my arm and yes my left arm is a little naked at the moment...

Here's my chisel pic Arnt.

Great craftsman pic Arnt.

Well I have been busy and let me tell you it's been slow going here but I am having fun.

Here is my completed back ready to have the plastic, temporary shield taped over my label to protect it during finishing.

This guitar will be braced a little heaver than I usually do so it can handle mediums and perhaps be a gasser.

I spent an entire day sharpening my edge tool world... In the last year I had made a list of things that I needed to improve on and sharpening chisels and plane irons was one of them. With a few additions to my shop and some ideas from some woodworking friends I think that I have this sharpening thing down now. Anyway all of my edge tools can pop hairs off my arm and yes my left arm is a little naked at the moment...

Here's my chisel pic Arnt.

- Nick

- Blackwood

- Posts: 3639

- Joined: Thu Feb 26, 2009 11:20 am

- Location: Christchurch, New Zealand

- Contact:

Nice chisel pic Hesh-meister, do you use the scary sharp system or machine assisted as in a Tormec? I've been told to get one from a cabinet maker/craftsman as it does a marvelous job. Your's certainly looks like it could take somebody's eye out

"Jesus Loves You."

Nice to hear in church but not in a Mexican prison.

Nice to hear in church but not in a Mexican prison.

Heshster, sharp tools are nice aren't they. I have a permanent bald spot on my left arm. I aim for being able to cut hair about half way up without bending it too much. Like you said, pop!

Nothing fancy, I just use a series of 6 Japanese water stones up to 8000.

The best thing I learned was the importance of flat stones. Dress your stones dead flat before each session. I have a flattening stone but you could use sandpaper on glass. Otherwise you will never get the whole back of the blade lapped properly. Then the bevel pretty much does itself.

Gasser???

Dom

Nothing fancy, I just use a series of 6 Japanese water stones up to 8000.

The best thing I learned was the importance of flat stones. Dress your stones dead flat before each session. I have a flattening stone but you could use sandpaper on glass. Otherwise you will never get the whole back of the blade lapped properly. Then the bevel pretty much does itself.

Gasser???

Dom

You can bomb the world to pieces,

but you can't bomb the world to peace!

but you can't bomb the world to peace!

I got a wet stone grinder and leather strop like the Tormek, but a fraction of the cost. Sure the Tormek might be the Rolls Royce of sharpening systems, but when you don't get much change from $1,000 it's hard to justify why you need one to the accountant.

Chisels and plane blade, as well as the kitchen knives come off the machine so sharp and so quickly that I don't even consider using one that is less than ridiculously sharp any more. The accountant likes her knives sharp, so it was a tick in the "Need" category.

Really nice interior label BTW Hesh.

Chisels and plane blade, as well as the kitchen knives come off the machine so sharp and so quickly that I don't even consider using one that is less than ridiculously sharp any more. The accountant likes her knives sharp, so it was a tick in the "Need" category.

Really nice interior label BTW Hesh.

sorry if i'm hijacking the thread, but this seemed relevant in light of the sharpening tools discussion - anyone know anything about this http://cgi.ebay.com.au/ws/eBayISAPI.dll ... K:MEWAX:IT ? Seems a lot more reasonably priced than the Tormek if (and only if) it does a great job.

Thanks guys!

Nick buddy I use a combination of the DMT diamond sharpening thing and Norton water stones. I have used the scary sharp method too but prefer water stones simply because once you have the stuff that you need there is nothing to ever run out of such as sand paper in certain grits.

The diamond sharpening thing is amazing and very fast too. Things that I used to struggle with such as getting a chisel into a rolling guide at exactly the same angle that the chisel already had I don't worry about anymore since the diamond sharpening thing will create a new bevel (as close as I can get to the original) in very fast order.

Norton stones are amazing too and really do a nice job. When needed I use the DMT to flatten my stones and that only takes less than a minute of rubbing the stone against the DMT.

I learned this method from Todd Stock from his YouTube video under the name of MDLuthier. Excellent method for sharpening!

The chisel in he pic is an LMI glue clearing chisel and it is mirror/razor sharp although the pic I posted did not focus correctly in the mirror surface of the chisel and it does not look as shiny as it actually is.

Dom absolutely! A sharp chisel is a dream to use and brace carving is already my favorite building activity so having sharp tools makes it even more pleasurable to me. Andy you are right, flat stones are a must too!

Gasser means a guitar built for bluegrass music also meaning loud and able to handle mediums (strings) since many bluegrassers use mediums. Remember that bluegrass guitarists have to play with banj*s so volume is important...

Allen bro thanks for the kind comments about my label. It's a pretty drawn out process to make these labels... but it is finally looking the way that I wanted it to. I spray the linen paper with lacquer after the label is printed and before I stick it on the back with 3M spray adhesive.

Nick buddy I use a combination of the DMT diamond sharpening thing and Norton water stones. I have used the scary sharp method too but prefer water stones simply because once you have the stuff that you need there is nothing to ever run out of such as sand paper in certain grits.

The diamond sharpening thing is amazing and very fast too. Things that I used to struggle with such as getting a chisel into a rolling guide at exactly the same angle that the chisel already had I don't worry about anymore since the diamond sharpening thing will create a new bevel (as close as I can get to the original) in very fast order.

Norton stones are amazing too and really do a nice job. When needed I use the DMT to flatten my stones and that only takes less than a minute of rubbing the stone against the DMT.

I learned this method from Todd Stock from his YouTube video under the name of MDLuthier. Excellent method for sharpening!

The chisel in he pic is an LMI glue clearing chisel and it is mirror/razor sharp although the pic I posted did not focus correctly in the mirror surface of the chisel and it does not look as shiny as it actually is.

Dom absolutely! A sharp chisel is a dream to use and brace carving is already my favorite building activity so having sharp tools makes it even more pleasurable to me. Andy you are right, flat stones are a must too!

Gasser means a guitar built for bluegrass music also meaning loud and able to handle mediums (strings) since many bluegrassers use mediums. Remember that bluegrass guitarists have to play with banj*s so volume is important...

Allen bro thanks for the kind comments about my label. It's a pretty drawn out process to make these labels... but it is finally looking the way that I wanted it to. I spray the linen paper with lacquer after the label is printed and before I stick it on the back with 3M spray adhesive.

Don't know about that one Brian. This is the model that I got at a local tool store for the $240 all up, and no shipping.

https://www.machineryhouse.com.au/Produ ... kCode=W860

https://www.machineryhouse.com.au/Produ ... kCode=W860

Thanks for the thoughts everyone.

I'm fine & well & have a 'way cool scar dude'

Finally spent a bit of time in the workshop yesterday.

The plane felt good in my hand and I enjoyed having curly shavings collect around my feet again.

Can't believe I've had 3 weeks off work & done nothing!

Back to work again Monday but I guess that means I'm allowed to operate machinery again

but I guess that means I'm allowed to operate machinery again

I'm fine & well & have a 'way cool scar dude'

Finally spent a bit of time in the workshop yesterday.

The plane felt good in my hand and I enjoyed having curly shavings collect around my feet again.

Can't believe I've had 3 weeks off work & done nothing!

Back to work again Monday

- J.F. Custom

- Blackwood

- Posts: 779

- Joined: Fri May 01, 2009 9:13 pm

- Location: Brisbane

- Contact:

Hi All,

Brian - There are a couple of things to watch with those machines. Not sure on that particular brand, evidently a Chinese unit, but Delta used to make one the same - also made in China. Perhaps they still do, however certainly not in 240v anymore.

They will do a good job but you need to be aware that the water stone used is very soft in nature. That in combination with the 'drip drip' of the water well can cause it to wear down very quickly - particularly if you don't move the 'drip line' frequently. So you will find you need to re-flatten often. These stones are also very expensive to replace - at least they were on the Delta model so it would pay to check with the supplier on availability and price of replacements before committing to a purchase.

Allen - The Scheppach units used to be made in Germany but are now made in China; hence the massive price fluctuations they have had over the years. Both German and Chinese models have had their batch problems but these have mostly been ironed out now. There should be no reason China can't manufacture a decent version as there is not a lot to the machine. If you manage to get a good one, as it sounds like you have, they will last and do a great job of sharpening as you know. The bonus with these machines are all the jigs you can purchase to sharpen everything else in the house! A great way to justify the expense to any financial controllers.

Tormek stand alone though in overall quality on the machine itself - but you pay for it. Same goes for DMT in diamond sharpening as mentioned by Hesh. Chinese diamond stuff varies in quality quite dramatically but they are good for the price you pay. DMT though will outlast any other and have more uniform controlled grits - again, you get what you pay for. You can't get a great finish off diamond though, hence why Hesh would follow up with the finer grits on the waterstones. All will do an excellent job of keeping tools sharp when used properly.

Craig glad to hear you're back at it, battle scars and all! Keep well.

Next time I'll post with what's on my bench rather than getting side tracked with the rest

Cheers,

Jeremy.

Brian - There are a couple of things to watch with those machines. Not sure on that particular brand, evidently a Chinese unit, but Delta used to make one the same - also made in China. Perhaps they still do, however certainly not in 240v anymore.

They will do a good job but you need to be aware that the water stone used is very soft in nature. That in combination with the 'drip drip' of the water well can cause it to wear down very quickly - particularly if you don't move the 'drip line' frequently. So you will find you need to re-flatten often. These stones are also very expensive to replace - at least they were on the Delta model so it would pay to check with the supplier on availability and price of replacements before committing to a purchase.

Allen - The Scheppach units used to be made in Germany but are now made in China; hence the massive price fluctuations they have had over the years. Both German and Chinese models have had their batch problems but these have mostly been ironed out now. There should be no reason China can't manufacture a decent version as there is not a lot to the machine. If you manage to get a good one, as it sounds like you have, they will last and do a great job of sharpening as you know. The bonus with these machines are all the jigs you can purchase to sharpen everything else in the house! A great way to justify the expense to any financial controllers.

Tormek stand alone though in overall quality on the machine itself - but you pay for it. Same goes for DMT in diamond sharpening as mentioned by Hesh. Chinese diamond stuff varies in quality quite dramatically but they are good for the price you pay. DMT though will outlast any other and have more uniform controlled grits - again, you get what you pay for. You can't get a great finish off diamond though, hence why Hesh would follow up with the finer grits on the waterstones. All will do an excellent job of keeping tools sharp when used properly.

Craig glad to hear you're back at it, battle scars and all! Keep well.

Next time I'll post with what's on my bench rather than getting side tracked with the rest

Cheers,

Jeremy.

- Dennis Leahy

- Blackwood

- Posts: 872

- Joined: Wed Oct 10, 2007 12:32 am

- Location: Duluth, MN, US

- Contact:

Craig,

More good wishes for continued recovery and health to you!

It is very encouraging that you're ready to get back to work, but do take your time before revving up to full blast. You've been through a lot, and it takes more than a few weeks to get you back up to normal. (My wife has had 2 brain surgeries, so I have an outsider's clue about the recovery.)

If you tell everyone that you're "fine", they'll assume you're fine, so be honest and take it in stages - plan to be around for many many more years, and you'll see that a few weeks is really not much time.

Dennis

More good wishes for continued recovery and health to you!

It is very encouraging that you're ready to get back to work, but do take your time before revving up to full blast. You've been through a lot, and it takes more than a few weeks to get you back up to normal. (My wife has had 2 brain surgeries, so I have an outsider's clue about the recovery.)

If you tell everyone that you're "fine", they'll assume you're fine, so be honest and take it in stages - plan to be around for many many more years, and you'll see that a few weeks is really not much time.

Dennis

Another damn Yank!

Dom my friend my label is set-up in Photoshop as "layers", 3 to be exact. The first layer is the text and graphics of the label and the second layer is set-up to be an actual photograph of the back wood that I may be using on a guitar. On this one I decided to not use an actual photograph of this guitar instead using an actual photograph of some BRW that I have used in the past.

The third layer is where I can add any text that I want such as the date, model, serial number etc. It is intended to be user changeable with each new guitar that I build.

Finally I sign the stinkin thing, let it dry over night, spray with lacquer, let it dry over night, spray with 3M spray adhesive (on the back side...) and then install. In addition it's printed on 100% linen with a mottled pattern in the paper.

It's a lot of trouble to go to but it's the best looking iteration of my label yet me thinks and I can customize the label to match the woods used on the guitar.

The third layer is where I can add any text that I want such as the date, model, serial number etc. It is intended to be user changeable with each new guitar that I build.

Finally I sign the stinkin thing, let it dry over night, spray with lacquer, let it dry over night, spray with 3M spray adhesive (on the back side...) and then install. In addition it's printed on 100% linen with a mottled pattern in the paper.

It's a lot of trouble to go to but it's the best looking iteration of my label yet me thinks and I can customize the label to match the woods used on the guitar.

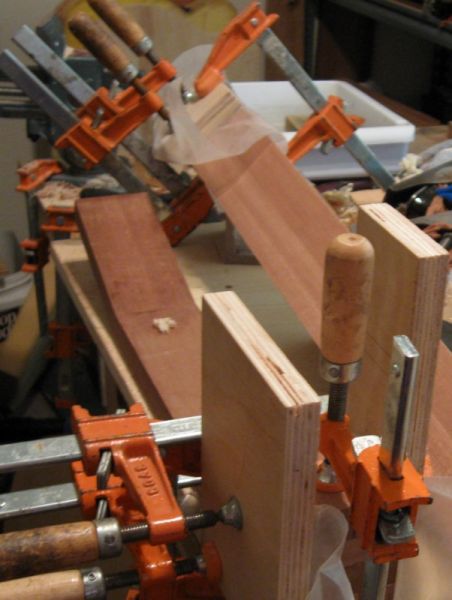

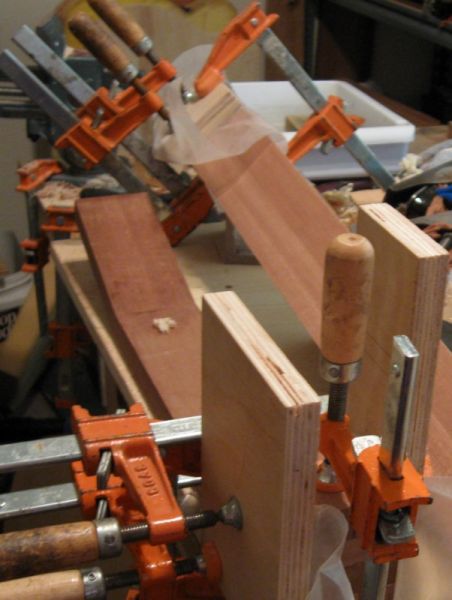

Progress can be measured in inches, right?

Hesh, don't look. It's not pretty.

Two neck blanks gluing up. One fought me the entire way and took most of yesterday to do. The other one took less than an half an hour.

Shoulder vice in use. Thanks again Craig for sharing. I really appreciate it.

The body is almost completely scraped. Just a little section to go. I can only a few minutes of scraping and then I have to stop for the day. The tendon to my right thumb about quit working when I started the scraping phase. It was so bad in the beginning that I needed to wear a brace for two weeks and then nothing in the shop for two months. Didn't quite follow doctor's orders, but I am trying not to push it to far.

Hesh, don't look. It's not pretty.

Two neck blanks gluing up. One fought me the entire way and took most of yesterday to do. The other one took less than an half an hour.

Shoulder vice in use. Thanks again Craig for sharing. I really appreciate it.

The body is almost completely scraped. Just a little section to go. I can only a few minutes of scraping and then I have to stop for the day. The tendon to my right thumb about quit working when I started the scraping phase. It was so bad in the beginning that I needed to wear a brace for two weeks and then nothing in the shop for two months. Didn't quite follow doctor's orders, but I am trying not to push it to far.

- Nick

- Blackwood

- Posts: 3639

- Joined: Thu Feb 26, 2009 11:20 am

- Location: Christchurch, New Zealand

- Contact:

Sorry to hear the Tendon problems that hindering your build Lillian

Even with two good thumbs, a decent session of scraping and my thumbs are aching so I can only imagine what you're going through.

The builds looking good tho! What is the binding you have used? It looks really good against the Mahogany

Even with two good thumbs, a decent session of scraping and my thumbs are aching so I can only imagine what you're going through.

The builds looking good tho! What is the binding you have used? It looks really good against the Mahogany

"Jesus Loves You."

Nice to hear in church but not in a Mexican prison.

Nice to hear in church but not in a Mexican prison.

- Bob Connor

- Admin

- Posts: 3126

- Joined: Mon Jul 09, 2007 9:43 pm

- Location: Geelong, Australia

- Contact:

- John Steele

- Blackwood

- Posts: 152

- Joined: Fri Mar 06, 2009 4:58 pm

- Location: Wilson, NY. 14172

- Contact:

I'll try not to disappoint Bob, but remember this guitar has been 7 years in the making. SO.... But I am getting closer.

John, Hesh's dog Sony is still looking for his smelling salts. I should have cleaned up I know, but if I had to make the shop Hesh viewable, well, I'd still be at it. But I agree, the rosewood does look so much better.

Thanks for the support guys.

John, Hesh's dog Sony is still looking for his smelling salts. I should have cleaned up I know, but if I had to make the shop Hesh viewable, well, I'd still be at it. But I agree, the rosewood does look so much better.

Thanks for the support guys.

Nice work there Lilian...coming along nicely.

If the cabinet scrapers are causing you grief then what you could try is the Veritas scraper holder....this little jig holds the curve in the scraper instead of you having to do it with your thumbs. I use mine sometimes when Ive got a long scraper session planned.

Cheers Martin

If the cabinet scrapers are causing you grief then what you could try is the Veritas scraper holder....this little jig holds the curve in the scraper instead of you having to do it with your thumbs. I use mine sometimes when Ive got a long scraper session planned.

Cheers Martin

What? Something that will allow me to work and not kill my thumb?? Oh baby, I'll have to look into that. Thanks Martin.kiwigeo wrote:Nice work there Lilian...coming along nicely.

If the cabinet scrapers are causing you grief then what you could try is the Veritas scraper holder....this little jig holds the curve in the scraper instead of you having to do it with your thumbs. I use mine sometimes when Ive got a long scraper session planned.

Cheers Martin

Who is online

Users browsing this forum: No registered users and 44 guests

[/img]

[/img]