As the other thread has been moved to the Gallery I thought I would start up a new thread for some of the CNCed inlay I have done. I will add to this from time to time if I do some interesting Inlay jobs.

This one is from a couple of years back. It is a faily straight forward design but the art deco symbol had about 16 pieces in it which fitted together nicely to form the finished product. I also devised a method for creating a dark border around light coloured shell which sits in light coloured timber. As part of the process of cutting the pocket I cut a 0.5mm border pocket around the outside of the inlay pocket. After the shell has been glued into place I sand the shell back to level. I then clean out the surounding pocket and fill it with Black plastibond. When that has hardened I sand back again to level.

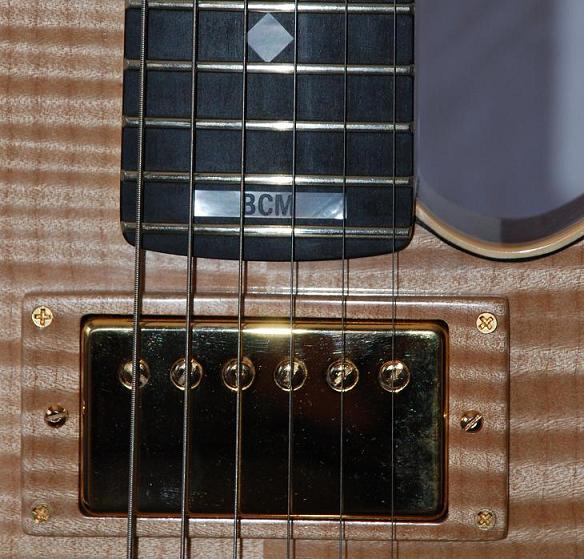

I also threw in a couple of photos of the 24th fret inlay with the customers Initials. Also the Pickup rings were made using my CNC machine too.

cheers, jb