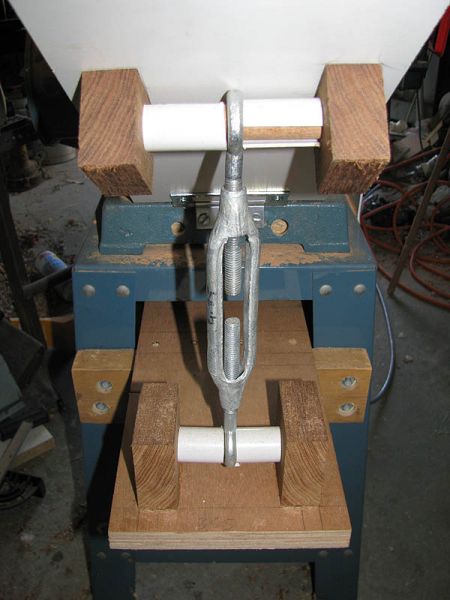

This is my take on shaping contours on the belt sander After Bobs tutorial on pre shaping braces I tried it for myself, and like I said I’m sold. I’ve posted photos of the before and after configuration. I will be modifying the table further

I find it more suitable to use the sander vertically for the many different sanding tasks used in doing my repairs and some building procedures, now I have a quick change machine.

The table shown came from a much larger machine [as did the sanding disc] and adapted for this machine possibly 15 years ago or so, and it’s the first time it’s been used like this. It’s adjustable up, down, in, out and can be angled. Maybe others will get some ideas from these photos.

Thanks for looking